Oragnizations experience thousands of dollars of lost revenue for every minute that their equipment is down, whether you are in a manufacturing facility, maintain a large fleet of vehicles, or maintain any critical infrastructure. The maintenance strategy you employ does impact your operational efficiency one way or the other.

We will be discussing the three maintenance strategies that have emerged, and are now actively used in the operational realm of the industrial space: reactive maintenance, predictive maintenance and preventive maintenance. Although all of these strategies attempt to eliminate the likelihood of equipment failure, they are different in how they approach the problem, their costs associated with implementation, and their successes related to minimizing equipment failure. Understanding these differences is important, especially as you need to make the necessary educated decisions to save your organization money and time.

Preventive Maintenance: The Scheduled Approach

Preventive maintenance is a method in which service is performed on equipment at a schedule, regardless of condition. Preventive maintenance, like changing the oil in your car every 3,000 miles or replacing air filters every 6 months, is based on a calendar and not based on issues.

Preventive maintenance is known as the process of performing required scheduled maintenance on equipment and machinery, rather than fixing the equipment or machinery after it unexpectedly stops functioning correctly. The purpose of preventive maintenance is to minimize the amount of unplanned downtime caused by unforeseen issues by identifying and preventing an issue occurring by having a preventive maintenance program.

By performing routine maintenance operations at regular intervals, preventive maintenance employs regular maintenance schedules to lower the likelihood that an asset would break down.

There are three key types of preventive maintenance have evolved which all involve performing maintenance in a repeatable way but have different schedules and fit into different operational applications for the business.

Usage-based preventive maintenance schedules carry out maintenance and inspections based on how much an asset is used, such as changing your car tires after you drive 50,000 miles.

Calendar or time-based preventive maintenance schedules maintenance at specific intervals, such as maintenance on your home furnace once per year.

Condition-based maintenance schedules are based on the wear and degradation of the asset.

Characteristics of Preventive Maintenance:

Scheduled Intervals: Maintenance tasks are planned for a specific time, or planned for a specific number of hours, or based on a specific number of miles or miles. It is not dependent on the true condition of the equipment.

Proactive Approach: Instead of waiting for equipment to break down, maintenance is performed before problems arise.

Focus on Equipment Lifespan: The focus is to see the equipment actions are happening at that level and hopefully extend the lifetime of the equipment by keeping on top of wear and tear.

Standardization: Procedures are usually standardized for the same type of asset or same model of asset

Example: A factory might have a preventive maintenance schedule that requires the replacement of filters every six months or a quarterly inspection of machinery to ensure its parts are not worn out.

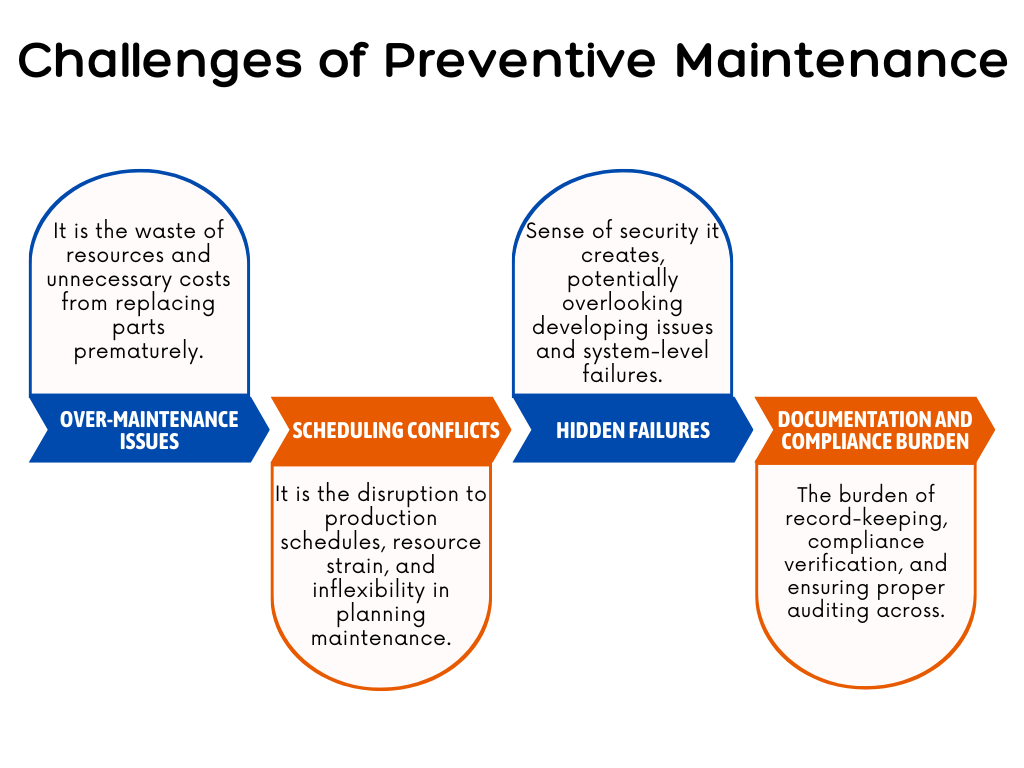

Challenges of Preventive Maintenance

While preventive maintenance offers many benefits, organizations often face several challenges when implementing this approach:

When equipment maintenance is followed strictly, it wastes resources by unnecessarily maintaining equipment. Replacing parts according to specific timeframes instead of their condition will prematurely replace parts that still have useful life left in them.

Scheduled maintenance is expensive; when equipment is taken out of service for scheduled maintenance it takes valuable staff time when, the equipment is still performing satisfactorily, no consideration is given to the actual situation of the equipment.

Scheduled maintenance shutdowns can impact production as the shutdown may interfere with peak production times or critical deadlines. Also, when several pieces of equipment are scheduled for maintenance at the same time, there is a strain on maintenance personnel along with production bottlenecks.

Scheduled or planned maintenance based on fixed timeframes also restricts the maintenance personnel from making flexible plans according to the operational needs or seasonality of how the equipment is used.

Routine maintenance can contribute to a false security blanket, potentially ignoring developing issues between each designated appointment. Common maintenance practices also may not find all potential failure modes, especially the ones that develop rapidly.

Additionally, maintenance practices mainly examine individual components and not the system in which parts interact, which may leave the problem unnoticed.

Recording detailed information for all scheduled maintenance events can be a heavy administrative task that leads to paperwork overload. Further, various regulations may require different frequency of maintenance thus complicating a schedule.

Other challenges are demonstrating compliance, verification of the performance of maintenance programs, and record keeping. Not to mention, there are significant issues around demonstrating everything is properly audited.

Predictive Maintenance: The Data-Driven Approach

Predictive maintenance takes a data-driven approach, using real-time monitoring and analytics to predict when equipment is likely to fail. Rather than following a fixed schedule, maintenance is performed only when data indicates that equipment performance is declining or failure is imminent.

Predictive maintenance leverages data analytics, sensor technology, and condition-based monitoring techniques to predict potential failures before they happen. Unlike preventive maintenance, which is based on a set schedule, predictive maintenance is driven by real-time data from equipment, helping organizations to make decisions based on actual asset health.

There are a number of condition monitoring techniques used to detect anomalies in assets and provide advance warning of potential issues which includes sound (ultrasonic acoustics), temperature (thermal), lubrication (oil, fluids), vibration analysis, or motor circuit analysis.

For example, a rise in temperature of a component, could indicate a rise in temperature due to airflow or coolant blockage, and unusual vibrations may indicate moving parts are misaligned or wearing out, and a change of sound may provide advance warning of faults that cannot be detected by human hearing.

The oil & gas sector was an early adopter of predictive maintenance in part to mitigate the risk of environmental disasters and other sectors are increasingly benefiting. In the food and beverage sector for example, severe health impacts could result from undetected food storage faults, and shipping can predict and prevent equipment malfunctions as repairs are less expensive to make in port than at sea.

Characteristics of Predictive Maintenance:

Condition-Based: Maintenance tasks are initiated by actual real-time data, suggesting that one part of the equipment is showing the potential for wear or failure.

Advanced Technologies: It utilizes significant components of sensors, IoT devices, machine learning, and AI to monitor the health of the equipment.

More Accurate Interventions: Maintenance is only performed when needed, based on the knowledge gained from continuous monitoring, and in doing so, it minimizes unnecessary downtime.

Cost-Effectiveness: By addressing the issue before it has a chance of causing equipment failures, Proactive Maintenance can help prevent expensive repairs and unplanned downtimes.

Example: A company might use IoT sensors to monitor vibration and temperature in a motor. If the data shows unusual patterns or exceeds predefined thresholds, a maintenance request is triggered, preventing a potential failure before it happens.

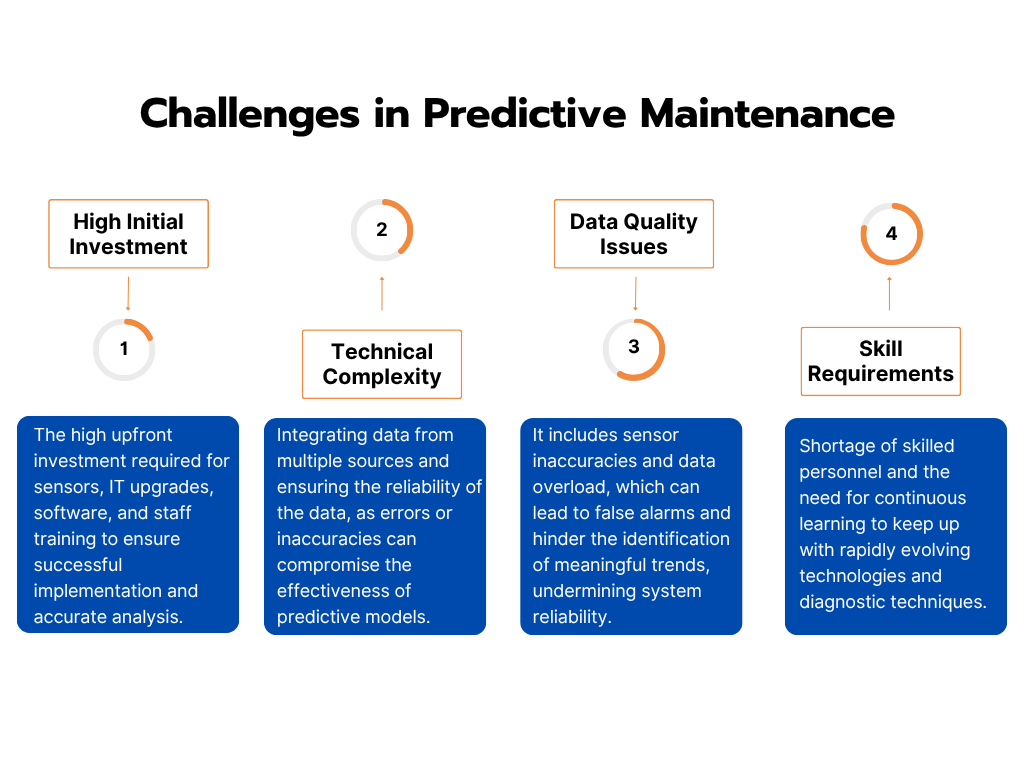

Challenges of Predictive Maintenance

Despite its advantages, predictive maintenance comes with its own set of implementation and operational challenges:

When implementing a predictive maintenance program, it incurs some considerable costs. Designing and deploying an operational predictive maintenance program involves costs for sensors, monitoring technologies, analysis software, etc.

Furthermore, enabling technologies will likely require upgrading of IT and networking capabilities, and data storage. Staff require training to assist with interpreting data, strategies to maximizing and utilizing new technology, and ensuring that condition-based maintenance decisions are based on completed and accurate analysis, all of which contributes to a significant investment for the predictive maintenance program to be successful.

Combining all the necessary data in predictive maintenance can be a technical challenge, requiring many times the need for specialist expertise due to this data coming from sensor, systems, and other sources, develop accurate predictive model that uses advanced analytics, and maintain the accuracy of the models over time and as the analytics advance.

Pertaining to reliability of the system as a whole, reliability of data is often overlooked or given less attention, because a system could be producing accurate predictive analytics based on an incorrect sensor or erroneous data communication relating to that data.

Sensor accuracy is vital, especially in the area of predictive maintenance, as faulty sensors, or poorly calibrated sensors, can provide unreliable data and lead to wrong maintenance decisions. Data from even a small number of sensors can also quickly turn into overwhelming amounts of data, making it increasingly difficult to find the actual trends and patterns within the data.

On top of this, an overly sensitive monitoring system can produce unnecessary false alarms, which can cause unnecessary maintenance actions and ultimately erode the confidence in the reliability and effectiveness of the monitoring system.

The success of predictive maintenance depends on personnel capable of working in specialized areas such as data analysis, vibration analysis, thermography, and other forms of diagnostic thinking. The job market can be challenging due to a lack of personnel with that skill level, and employing such programs can make things even more difficult.

As technology is moving quickly, maintenance teams must learn continuously, and find ways to develop their skills, in order to adapt to new tools and technology, and to make predictive maintenance successful over time.

Minimize Downtime with Predictive Maintenance – Get Your Custom Solution Now

Key Differences Between Preventive and Predictive Maintenance

Scheduled based on time or usage intervals

Data-driven, based on actual asset conditions

Lower initial investment in technology and training

Higher upfront investment in sensors, software, and training

Regular intervals regardless of asset condition

Performed only when necessary, based on data

Relatively simple to implement and manage

More complex implementation requiring specialized technology

Risk of unnecessary maintenance or missed issues

Minimizes risk of unplanned breakdowns

Can lead to unnecessary downtime and resource allocation

Reduced downtime with more efficient resource usage

Requires maintaining large inventories of spare parts

Reduces spare parts inventory through better demand forecasting

When to Choose Preventive Maintenance

Preventive maintenance is ideal for:

Critical safety equipment – Where equipment failure could have a serious safety, financial, or environmental impact, following a scheduled preventive maintenance is a more effective way to ensure safety standards are met.

Low-cost equipment – For equipment that is inexpensive, the cost of setting up monitoring technology may be greater than the value of the equipment.

Simple systems – Where the maintenance procedures are simple enough that implementing a complex condition monitoring system does not make good economic sense.

Regulated industries – Many industries and sectors have compliance requirements that mandate a defined maintenance schedule and procedure.

Limited technical resources – Where the organization may not have significant technical skill or capacity to be implementing predictive maintenance.

Industries that benefit from preventive maintenance:

Food and beverage

Healthcare facilities

Transportation (due to compliance and safety of safety-critical systems)

Small manufacturing operations

Facilities management

When to Choose Predictive Maintenance

Predictive maintenance is most effective for:

High Value Equipment – Costly machinery where the impact of an unintended failure is high.

Critical Production Equipment – Machinery that would cause significant delays if it failed.

Complex Systems – Equipment with several failure modes that needs to be monitored routinely.

Variable Operating Condition – Equipment that operates with variable loads, temperatures, and any other harsh physical conditions.

Experienced Technical Teams – Organizations with knowledgeable technicians that can interpret the data and make informed decisions.

Industries that benefit from predictive maintenance:

Oil and gas production

Power generation

Chemical processing

Heavy manufacturing

Data centers

The Importance of Data Management in Contemporary Maintenance Practices

Regardless of which maintenance approach you choose, effective data management is crucial for success. Poor data quality can lead to:

Incorrect maintenance decisions

Missed maintenance opportunities

Duplicate work orders

Inaccurate equipment histories

Compliance issues

Future Trends in Maintenance Management

The maintenance landscape keeps changing as technology develops further:

Artificial Intelligence: We are seeing more advanced AI algorithms which are better equipped to predict equipment failures along with empowering us to improve our schedule and methodologies for maintenance.

Internet of Things (IoT): More sensors or connected devices create improved data for decision-making in a maintenance sense.

Augmented Reality: AR technology helps technicians see a visualization of equipment problems and procedures in following maintenance.

Digital Twins: Systems which operate in a “virtual“ clone of the original system; they build simulations and predictive models.

Cloud Computing: Meaning I can now access maintenance management systems that are based in the cloud, which affords tremendous scalability on a cloud service, and the possibilities are opening for organizations of every size.

Conclusion

It is up to the organizations these days to determine the best predictive and preventive maintenance method to use; both methods (predictive and preventive) have benefits. Preventive maintenance is simple, often predictable, and a relatively low initial investment, which is the case in many organizations and many types of equipment. Predictive maintenance looks for optimization, efficiency, and cost savings of the entire process, especially in areas where there is criticality and expensive equipment.

For many of these organizations who have been successful, the model is hybrid. They have preventive maintenance as the base, and apply predictive maintenance on a limited basis, to their most critical assets. The organizations get the reliability from a scheduled maintenance program, while simultaneously getting the efficiency in terms of workload from a conditioned-based maintenance (predictive) program.

While it does not matter if you use a preventive, predictive, or hybridized maintenance strategy, you have to understand this first and foremost. Clean and accurate data and good data management practices are the foundation for success. If you do not have trusted data, then no maintenance strategy – no matter how sophisticated – will have credibility.

With an advancing and more cost effective technologies, predictive maintenance strategies will get closer to being what is currently known as standards on more types of equipment and more types of industries. However, preventive maintenance strategies will still be applicable in a wide variety of possible application scenarios: based on simplicity, compliance or cost for example.

The key is to start with a clear understanding of your organization’s needs, capabilities, and constraints, then choose the maintenance strategy that best aligns with your operational goals and available resources. With the right approach, you can minimize downtime, reduce costs, and maximize the value of your equipment investments.