Item Master Data refers to a structured and standardized set of attributes that define the materials, spare parts, or products used within an organization. It acts as a central template or reference record within ERP, EAM, or inventory systems, ensuring consistency and accuracy across procurement, manufacturing, and maintenance processes.

It refers to the core set of information used to identify and describe individual items – such as materials, products, components, or spare parts—within a business system like an ERP (Enterprise Resource Planning) or MRP (Material Requirements Planning) system.

Organizations like SAP and Oracle have defined item master in different terms and under various modules. Like in Oracle they have referred to item master under the module Oracle Inventory Management.

In SAP, the equivalent is called the Material Master, managed primarily through the Materials Management (MM) module. Despite the difference in terminology, both serve the same core function – to ensure consistent, accurate, and centralized material data across procurement, production, maintenance, and finance operations.

Item Master Data is a vital component of various business systems like Material Resource Planning (MRP), Enterprise Resource Planning (ERP), and MRO (Maintenance, Repair, and Operations) cataloguing systems. By providing accurate and up-to-date information, it helps organizations streamline their day-to-day operations, reduce errors, and make informed decisions.

Proper management of Item Master Data ensures that businesses can track materials, optimize inventory, improve procurement processes, and maintain operational efficiency, ultimately supporting smoother workflows across departments such as purchasing, manufacturing, and maintenance.

Key Elements of Item Master

Item number or code (a unique identifier)

Item description

Unit of measure (e.g., pieces, kilograms, liters)

Material type or category

Manufacturer details

Lead time

Stocking levels and reorder points

Pricing and cost information

Classification codes (e.g., UNSPSC, ECCN, HSN)

Technical specifications (e.g., dimensions, weight, voltage)

Why is Item Master Data Important?

Procurement and Sourcing

Accurate descriptions help procurement teams identify and source the correct materials or parts without confusion.

Standardized names and attributes prevent duplicate items from being created, which avoids maverick or redundant purchases.

Manufacturer and supplier links in item master records ensure orders go to approved vendors, reducing risks and enhancing compliance.

Pricing data in the item master ensures correct cost calculations and budgeting for purchase orders.

Inventory Management

Consistent units of measure prevent overstocking or understocking due to misinterpretations (e.g., ordering 100 meters instead of 100 rolls).

Proper classification allows accurate tracking of item usage, turnover rates, and criticality.

Stocking policies (like min/max levels and reorder points) stored in item records drive automated replenishment processes.

Avoidance of duplicates means the same part isn’t stocked in multiple locations under different names, tying up working capital.

Supply Chain Planning

Demand forecasts and material planning are built on historical item usage. If duplicate records exist, forecasting is skewed.

Lead time data (stored in the item master) is essential for planning inbound deliveries and maintaining production flow.

BOMs (Bills of Materials) depend on item master accuracy. If part numbers are mismanaged, it disrupts production schedules.

Logistics optimization requires knowing the size, weight, and handling requirements of items — all stored in the item master.

Maintenance Operations (Especially in Manufacturing & Asset-Intensive Industries)

Spare parts identification during preventive or corrective maintenance requires clarity. Incorrect data can lead to delays or wrong parts being issued.

Linkage to equipment BOMs ensures technicians can find and request the right part quickly.

Criticality flags and stock levels help prioritize stocking of essential spares to reduce downtime.

Cross-referencing manufacturer part numbers supports quick sourcing in emergencies.

Background of Item Master Data

Item Master Data forms the backbone of Oracle ERP operations, holding essential information about every product a business buys, makes, or sells. It ensures consistency across modules like procurement, inventory, and manufacturing, enabling accurate transactions and efficient decision-making.

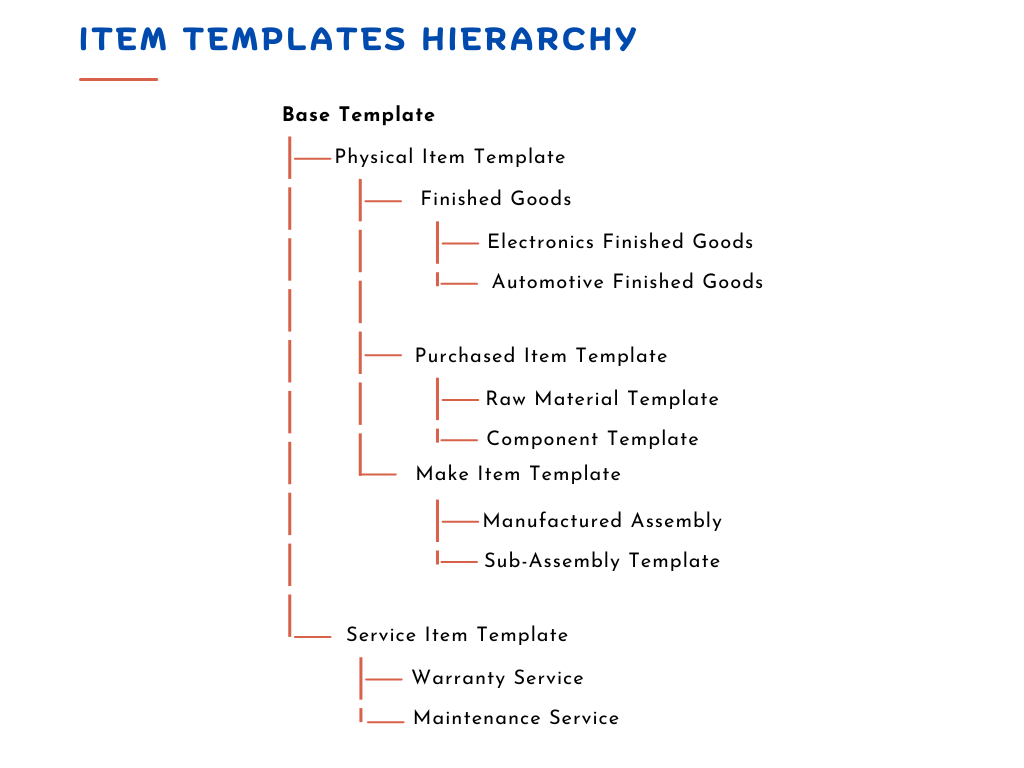

Item Templates

When you’re creating items in Oracle, there are hundreds of attributes to fill out – from inventory controls to costing methods. That’s where templates come in. Item templates act as pre-configured sets of attribute defaults. They simplify the process and reduce errors by ensuring consistency.

Finished Good Template: Used when you’re creating manufactured, sellable items. It sets defaults for WIP (Work-in-Process), costing, and sales attributes.

Purchased Item Template: Useful for items that are bought from suppliers. It disables manufacturing-related flags and enables procurement-relevant ones.

Make Item Template: Focuses on internal manufacturing. Sets flags for routings, work orders, and BOM associations.

Inventory Item Template: Basic template for items stored in stock but not necessarily sold or manufactured.

Cross-References and Catalogs

Oracle systems often deal with multiple stakeholders – each using their own codes for the same item. Cross-references make this manageable.

Customer Item Numbers: Sales reps may need to take orders using a customer’s naming convention. This mapping ensures that the internal item is correctly identified when a customer references “Part XZ-789.”

Supplier Item Numbers: When raising POs, procurement teams can reference a supplier’s item code, even though Oracle uses a different internal code. This ensures clarity on the PO and reduces confusion.

Manufacturer Part Numbers: Helps in traceability, especially in industries like aerospace or electronics, where components from different manufacturers must be tracked.

Catalogs and Categories: These organize items in a way that makes searching and grouping easier — especially useful in self-service procurement systems, ecommerce platforms, or MRO environments.

Ultimately, cross-references reduce human error and streamline communication across systems and partners.

Item Categories and Catalogs

Not all items are managed the same way. Some are direct materials, others are MRO supplies. Oracle lets you segment items using Category Sets, and each set can serve a different purpose.

Searching: Users can find parts more easily when they’re organized under meaningful categories (e.g., Bearings > Ball Bearings).

Reporting: Spend reports, cost rollups, or aging inventory analyses often slice data by category.

Planning/Procurement: Forecasts or safety stock levels can be applied differently for “Raw Materials” versus “Spare Parts.”

You can have multiple category sets – a purchasing category might focus on vendor strategy, while a costing category helps in allocating costs. This segmentation is powerful and essential for large enterprises with complex supply chains.

Item Relationship

Items don’t exist in isolation – they’re often linked to others for operational, planning, or substitution purposes.

Substitutes: If an item is out of stock, its substitute can be automatically suggested in order entry or planning systems. This helps maintain service levels during disruptions.

Superseded Items: Over time, items become obsolete and get replaced. Oracle maintains this lineage so that historical records stay valid, while planning and procurement shift to the new part.

Co-/By-products: In process manufacturing (e.g., food, chemicals), making one item often yields others. Oracle lets you define co-products (planned, valuable) and by-products (secondary, maybe recyclable) during recipe setup.

These relationships are critical for planning accuracy, inventory availability, and lifecycle management.

Item Lifecycle & Status Control

Item statuses dictate what can and cannot be done with a product at a given time.

Item Status Codes: Help indicate where the item is in its lifecycle — for example, “New” (not yet approved), “Active” (available for transactions), or “Obsolete” (blocked from new usage but still reportable).

Status Controls: Determine where the item can be used — maybe it’s allowed in inventory but not in sales, or it’s purchasable but not manufacturable.

PLM Integration: When you use Oracle Product Lifecycle Management, status changes (like “Design Complete” or “Released to Manufacturing”) automatically flow into Inventory and BOM systems.

This ensures that engineering, procurement, and operations are always aligned, and obsolete items don’t sneak into production runs.

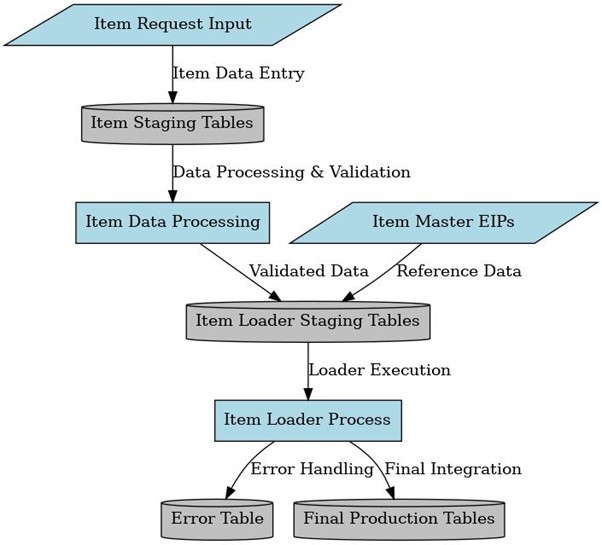

How Item Master Data is Created

The item master data process starts with capturing key details like item name, type, and unit of measure. From there, templates are applied to auto-fill standard attributes, and the item is categorized for inventory, purchasing, or planning use.

Approval workflows and validations ensure the data is accurate and complete before the item becomes available across Oracle ERP modules.

Step 1: Item Request Input (Start Point)

This is the initial stage where item-related data is captured and entered into the system.

Data can originate from multiple sources including procurement teams, project teams, engineering, design, suppliers, manufacturing departments, and external third-party systems.

The data captured at this stage includes:

Product Specifications: Technical characteristics, size, weight, materials used, etc.

Item Descriptions: Detailed descriptions that accurately identify the item.

Pricing: Costing information and pricing strategies.

Unit of Measure (UOM): The unit in which the item is measured, such as kg, meters, liters, etc.

Classification: Categorizing items using internal classification systems or standard coding systems (e.g., UNSPSC, eCl@ss)

Data Enrichment: Supplementing initial data with missing attributes (e.g., supplier information, manufacturer codes) that may not be included in the initial input.

Step 2: Item Staging Tables

After the initial data entry, the information is temporarily stored in staging tables to perform preliminary validation checks before integration into the live system.

Buffer Role: Staging tables act as a temporary holding area, enabling the system to validate and clean data before it enters production environments.

Data Quality Assurance: Initial checks to identify missing fields, format errors, and inconsistencies between different sources.

Performance Optimization: The data in staging tables is optimized for processing, which improves system performance and allows for parallel processing of multiple records.

Step 3: Item Data Processing

Data in staging tables undergoes extensive validation, enrichment, and standardization to ensure consistency and data quality.

Data Validation: Ensuring all mandatory fields are populated and adhere to defined formats (e.g., date formats, numeric values).

Enrichment: Adding additional information where required (e.g., supplier-specific attributes, cross-referencing data from external sources).

Data Standardization:

Categorization Mapping: Items are mapped to the appropriate internal categories and classification standards.

Currency and Pricing Standardization: Ensuring that pricing information aligns with currency codes and valid price ranges.

Duplicate Detection: Running algorithms to identify and merge duplicate records based on predefined criteria (e.g., item description, manufacturer part numbers).

Step 4: Item Loader Staging Tables

After data has passed preliminary validation in staging, it is transferred to Item Loader Staging Tables, an intermediary step where additional, more comprehensive checks are performed.

Pre-Integration Quality Check: The loader staging tables allow for more rigorous validation such as:

Cross-checking against external reference data (e.g., existing product catalogs, classification systems).

Verification against Item Master EIPs (Enterprise Integration Points) for consistency with external data sources.

Integration with Third-Party Systems: Ensures seamless synchronization of data with external systems (e.g., supplier data feeds, engineering databases).

Step 5: Item Loader Process

The Item Loader Process automates the transfer of validated, enriched, and structured data from the staging area into the live, operational systems. It follows as:

Automation & Scheduling: This step is typically automated to run periodically or based on pre-defined schedules to ensure real-time data integration without manual intervention.

Data Mapping and Transformation: The loader ensures that data is mapped correctly into final production tables and that data formats are transformed to meet system requirements (e.g., converting units of measure, converting currency values).

Error Logging: Any discrepancies or issues encountered during the loading process are recorded in the Error Table for further investigation and resolution.

Step 6: Error Tables

The Error Table acts as a log and repository for items that could not be loaded successfully into the live system.

Types of Errors:

Missing or incomplete data (e.g., missing supplier details, pricing, or mandatory fields).

Invalid or out-of-range values (e.g., pricing inconsistencies, wrong UOMs).

Data format violations (e.g., incorrect date format, invalid part numbers).

Error Correction: Data errors must be identified, corrected, and tested before re-attempting to load into production systems.

Automated Alerts: The system can be set up to trigger automated notifications or workflows when errors are logged, improving response times.

Step 7: Final Production Tables

After the item data undergoes all the validations and quality checks, it is merged into the Final Production Tables.

System-wide Access: The completed item data is stored in the central database, available to different business functions like:

Purchasing and Procurement: Providing accurate and current product information for purchasing.

Inventory Management: Supporting inventory planning, tracking, and reporting.

Sales and Distribution: Providing sales teams with accurate product information for customer engagement.

Supplier Relationship Management: Simplifying communication and interaction with suppliers on the basis of the most accurate item records.

Engineering and Manufacturing: Supplying product specifications critical to production and product lifecycle management.

Data Governance: Ensures that the ultimate production data conform to enterprise data governance policies, such as ownership, access control, and auditing.

Step 8: Item Master EIPs (External Data Reference)

Enterprise Integration Points (EIPs) are outside sources of data that act as a reference point for maintaining consistency and accuracy of item information throughout the organization. Important EIPs are:

Supplier-provided Data: Supplier catalogs and product specifications that augment internal item data.

Engineering Change Management (ECM) Updates: Outside systems that give updates on design changes or new specifications for items.

Industry Classification Standards: Making sure the items comply with external classification standards like UNSPSC, eCl@ss, PIDX, or ISO-based item coding to ensure consistency between industries.

Data Synchronization: EIPs enable the synchronization of item data with external catalogs and data repositories, providing real-time updates and the incorporation of the most current product information.

Item Master vs. Inventory Master vs. Material Master

Item Master: Focuses on comprehensive details of an item, including specifications, pricing, suppliers, and descriptions.

Inventory Master: Concerned with stock levels, warehouse locations, and the current availability of inventory items.

Material Master: Covers materials used in manufacturing processes, including raw materials, work-in-progress, and finished goods.

Quality of Item Master Data

Single Source of Truth: Ensures consistency and accuracy of item-related data across departments.

Poor Data Quality Consequences: Leads to inefficiencies, operational errors, stockouts, overstocking, inefficient purchase process which leads to financial losses.

Item Master Role Data Management (MDM)

Product Lifecycle Analysis: Tracks product lifecycles from creation to obsolescence, allowing for timely decision-making.

Direct Users: Procurement, supply chain management, manufacturers, and inventory management teams.

Indirect Users: Materials requirement planning, supplier relationship management, and engineering teams.

Item Master - Important Attributes

Item Master Data consists of various attributes that define and categorize each item in a structured way. These attributes help in efficient inventory management, procurement, and product lifecycle tracking. Below are the key components:

Structure of Item Master

The Item Master follows a structured format, ensuring uniformity across all items in the database.

It is categorized into a hierarchy of main categories and sub-categories based on shared characteristics.

Key attributes include:

- Item Name – The standard name of the item.

- Item Code (SKU/Part Number) – A unique identifier assigned to each item.

- Description – Detailed information about the item, including specifications and usage.

- Unit of Measure (UOM) – Defines how the item is measured (e.g., kg, liter, drum, feet, each, piece etc.).

- Classification – Assigns the item to a relevant category (e.g., raw material, spare part, finished product).

Item Categories

Items are grouped into specific categories to simplify identification and management.

Common classifications include:

- Raw Materials - Used in production processes (e.g., metals, plastics, chemicals).

- Finished Goods – Final products ready for sale or distribution.

- Spare Parts – Replacement components for machinery or equipment.

- Consumables – Items used in daily operations (e.g., lubricants, fasteners, safety gear).

Categorization improves searchability, reporting, and stock management efficiency.

Inventory Data Tab and Stock Levels

Inventory-related data is crucial for tracking stock movement and replenishment strategies. Learn more about effective inventory management practices here.

Inventory Data

Attributes related to stock management:

Stock Levels – The current quantity available in inventory.

Reorder Points – Minimum stock level before replenishment is needed.

Lead Time – Estimated time required to procure or manufacture the item.

Safety Stock – Extra quantity kept preventing stockouts.

Stock Levels and Hierarchy

Inventory is structured across multiple levels for better tracking:

Warehouse Level – Identifies the storage location (e.g., main warehouse, regional depot).

Bin/Shelf Level – Specifies the exact storage position within a warehouse.

Lot/Batch Tracking – Helps in quality control and expiry tracking (for perishable goods).

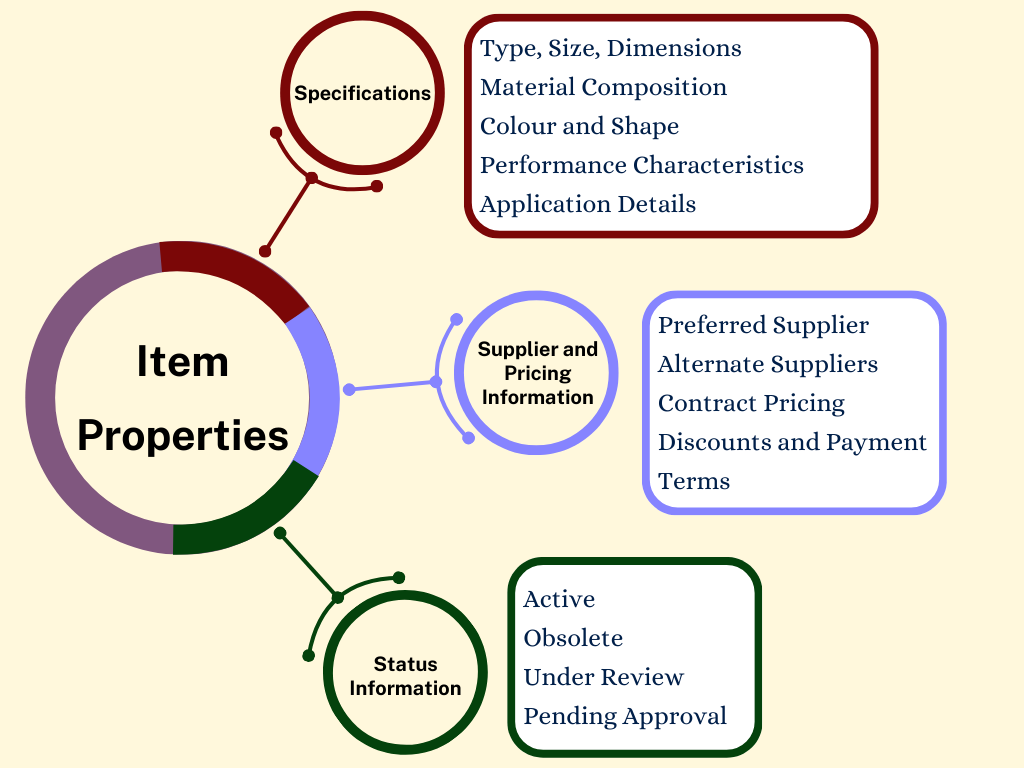

Item Properties

Each item has detailed specifications that define its physical and procurement-related attributes.

Specifications

Includes precise product details such as:

Type, Size, Dimensions

Material Composition

Colour and Shape

Performance Characteristics

Application Details

Supplier and Pricing Information

Captures supplier-related details:

Preferred Supplier – The main vendor supplying the item.

Alternate Suppliers – Backup vendors in case of stock unavailability.

Contract Pricing – Agreed price for bulk purchases.

Discounts and Payment Terms – Negotiated pricing and payment schedules.

Status Information

Defines the current state of the item:

Active – Item is in regular use.

Obsolete – Item is no longer in production or use.

Under Review – Item is being evaluated for changes or discontinuation.

Pending Approval – Item is awaiting authorization before inclusion in the master database.

Why Are These Attributes Important?

Accurate Data Management: Avoids duplication and inconsistencies.

Better Procurement Decisions: Ensures the right suppliers and pricing are used.

Improved Inventory Control: Prevents stockouts or overstocking.

Standardization: Enhances compatibility across different business units (procurement, supply chain, finance, etc.).

Compliance & Auditing: Ensures adherence to industry regulations and standards.

Having a well-structured Item Master Data with clear attributes enables organizations to streamline operations, enhance decision-making, and ensure data integrity. These attributes act as the single source of truth, providing a consistent and reliable dataset for procurement, inventory management, and production planning.

Item Master Data Implementation Practices

Data enrichment through structured categorization and attribute mapping.

Establish item hierarchies and revision tracking through Engineering Change Management (ECM).

Implement multi-organizational structures at master and organizational levels.

Define cross-reference attributes for suppliers, customers, and manufacturers.

Conduct audits to identify duplicates, missing fields, and anomalies.

Maintain input information, product details, financial records, and forms for data entry.

Governance Workflow: Establish clear data ownership, maintenance templates, and data interconnectivity.

Attribute Repository: Maintain a repository for structured attribute management.

Data Quality Rules: Implement deduplication, validation, mapping, and taxonomies.

System Integrations: Ensure compatibility with ERP, SCM, and procurement systems.

Monitoring and Maintenance: Continuous updates and audits to maintain data integrity.

Ensure consistency through standardized classification and attributes.

Integrate Item Master Data with business-critical systems.

Establish clear governance policies and workflows.

Conduct regular audits to identify discrepancies or shortfalls.

Maintain cross-functional collaboration between departments.

Implement automated tools for data validation and management.

By implementing robust Item Master Data practices, organizations can enhance efficiency, minimize errors, and optimize their supply chain and inventory management processes.

Conclusion

In summary, successful Item Master Data Management is crucial to having your organization maintain correct, consistent, and current data on all materials, products, and spare parts. Proper data management results in enhanced operational effectiveness, fewer errors, and more effective decision-making across different business functions such as procurement, inventory management, and maintenance.

By centralizing and structuring item information, companies can automate their processes, improve interdepartmental collaboration, and ultimately gain a smoother, more efficient workflow. Having strong Item Master Data practices in place ensures that your company is adequately prepared to manage the intricacies of today’s operations and fosters long-term success.