The idea of ascertaining criticality in spare parts emerged as asset-intensive corporations realized that oversight in production operations, safety, and inventory management has a direct impact on profitability and supply chains.

Put simply, certain spare parts are critical because their unavailability can lead to significant downtime, safety risks, or financial losses.

This is especially important in industries with complex, large-scale production operations and MRO (Maintenance, Repair & Overhaul) processes.

Defining Criteria for Critical Spares

Criticality of a spare part and a fixed asset are inextricably linked, and while the criteria for these definitions may vary from org to org, the factors that help define criticality largely remains the same.

- Impact on Production Operations

If the spare part, analysed along with its dependent equipment, is one that can stall production operations or result in prolonged downtime, the spare part is likely to be flagged as a critical spare part to ensure adequate stocking + safety stock pertaining to that part is maintained.

- Coste del tiempo de inactividad

Not all fixed assets or equipment are part of key production processes. Spare parts linked to such fixed assets, that are part of non-core production activities are not likely to be flagged as critical parts since they do not hamper core production operations, and ultimately there’s no serious financial impact due to the downtime

- Operational Criticality

If the piece of machinery or asset can operate for a certain amount of time without adverse harm, even in the absence of the given part, then it is unlikely to be tagged as “Critical”.

Conversely, if the piece of machinery is key to the production process and if the spare part is an indispensable piece of the production process, the part should be flagged as “Critical”

- Health & Safety Risks

Absence of spare parts, that are likely to lead to health and safety concerns are a flagged as critical, especially given OSHA guidelines. Conversely spares that don’t lead to HSE risks are also less likely to be tagged as “critical spares”

- Supplier Lead Time

Spare Parts or consumables with much longer lead times right from procurement to physical delivery are higher up in the criticality matrix as opposed to parts with lower lead times. Higher supplier lead times are likely to result in much prolonged downtime directly affecting production schedules, losses and profitability.

The goal of any such criticality assessment is to classify the nature of a spare part into a pre-defined segment, which is generally, critical, semi-critical or non-critical but these practices vary from even industry to industry and even company to company.

Who Can Relate to This?

The insights on spare parts criticality are most relevant to professionals such as:

for driving efficiency and reducing operational risks.

for managing spare parts planning and failure prevention.

for ensuring uptime, safety, and optimized performance.

for balancing supplier reliability with inventory costs.

for improving stocking accuracy and reducing surplus

for reducing unplanned downtime and enhancing asset performance through trusted data

These roles are especially critical in asset-intensive industries such as:

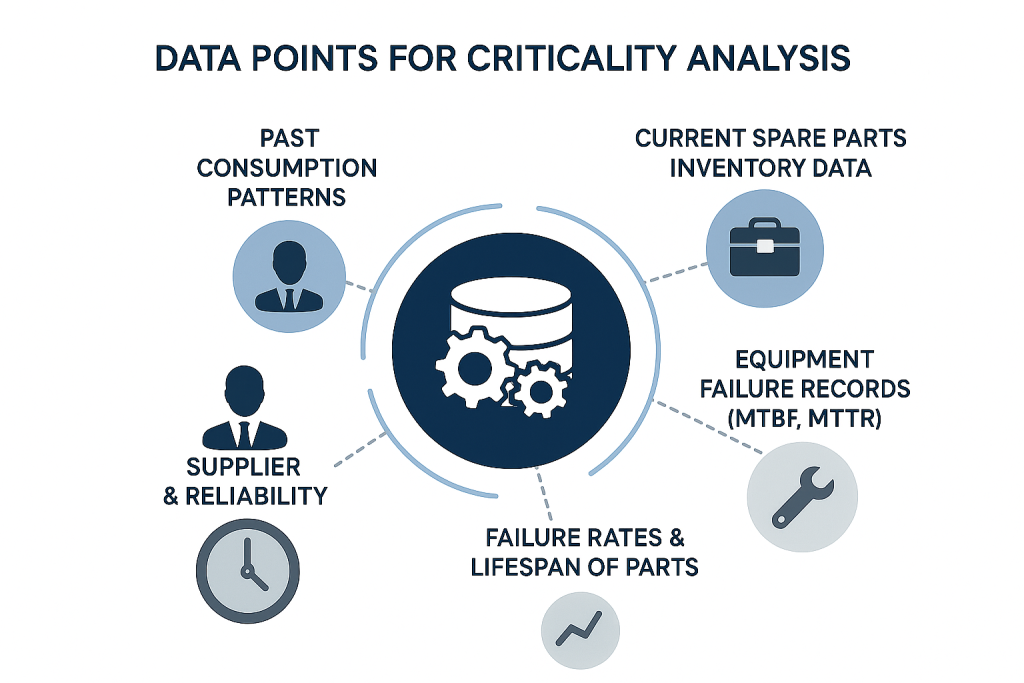

Data Points Relevant to Criticality Analysis

Here are some data points that are relevant to any criticality study

- Past Consumption

- Available Spare Parts Data

- Analyzing Equipment Failure Data including Mean Time Between Failures & Maintenance records

- Analyzing Spare Parts with high Failure Rates or Limited Lifespans

- Supplier Lead Time Data

Classification Framework

Organizations typically classify spare parts into three categories:.

Essential to plant operations or safety (e.g., turbines, pumps, safety systems).

Important but with redundancies or workarounds available.

Supportive, non-essential items.

Methods of Criticality Analysis

As one can imagine, a criticality study can be based on a pre-existing standard, customized over that standard or be completely crafted from scratch.

The exact criticality analysis approach will vary wildly based on industry or company.

Here are a few standard approaches that are well-known and generally adopted

- Failure Modes and Effects Analysis (FMEA) Based RPN Scoring

In this method, the part failure is analysed based on three core factors, all of which are scored on a scale (typically 1-10). 1 being low impact an 10 being high impact.

- Severity (S): How serious is the impact if the part fails?

- Occurrence (O): How frequently does the part fail?

- Detection (D): How easily can failure be detected before it results in business implications?

For each part, the calculation as a product of the individual scores.

RPN Calculation: = S×O×D

- Parts with higher RPN are considered more critical.

In this method, the part failure is analysed based on three core factors, all of which are scored on a scale (typically 1-10). 1 being low impact an 10 being high impact.

- Severity (S): How serious is the impact if the part fails?

- Occurrence (O): How frequently does the part fail?

- Detection (D): How easily can failure be detected before it results in business implications?

For each part, the calculation as a product of the individual scores.

RPN Calculation: = S×O×D

- Parts with higher RPN are considered more critical.

Let’s take the example of a Pump Motor Bearing;

|

Factor |

Rating |

Reason |

|

Severity (S) |

8 |

Failure stops production line. |

|

Occurrence (O) |

5 |

Fails once every 2 years. |

|

Detection (D) |

7 |

Hard to notice before failure. |

RPN Score in this case is = 8×5×7 = 280

In another case, let’s take the example of a Conveyor Belt Sensor:

|

Factor |

Rating |

Reason |

|

Severity (S) |

5 |

Only minor delay in production. |

|

Occurrence (O) |

5 |

Fails every year. |

|

Detection (D) |

3 |

Easy to detect before failure. |

RPN Score in this case would be = 5 X 5 X 3 = 75

Based on this, it is easy to see that the Conveyor Belt Sensor has a lower criticality rating when compared to the Pump Motor Bearing and the motor bearing should have a higher priority in spare part inventory and preventive maintenance planning.

Quite a few software systems make use of RPN-based scores to ascertain criticality.

For Instance:

In Infor EAM, you enter S, O, and D values for each part, and the system automatically calculates RPN and ranks parts accordingly.

Implications on Maintenance Decision Making

- Inventory Strategy: Keep high RPN parts on-hand; low-RPN parts can be ordered as needed or the inventories can be reduced significantly

- Planificación del mantenimiento: Schedule Preventive Maintenance for high-RPN items

- Procurement Management: Ensure quicker Turnaround Times for high RPN parts along with a multi-supplier options

- Uses pre-defined criteria like operational impact, safety, cost, lead time, etc.

- Each criterion is weighted, normalized, and summed to produce an overall score.

- Pros: more flexible, can include non-FMEA criteria like supplier reliability or spare availability.

Practical Use:

- A plant uses weighted scoring to rank all spare parts. Parts with scores above 80/100 are labelled “critical,” 50–79 “semi-critical,” below 50 “non-critical.”

- The system can then generate reports, dashboards, and alerts for critical parts.

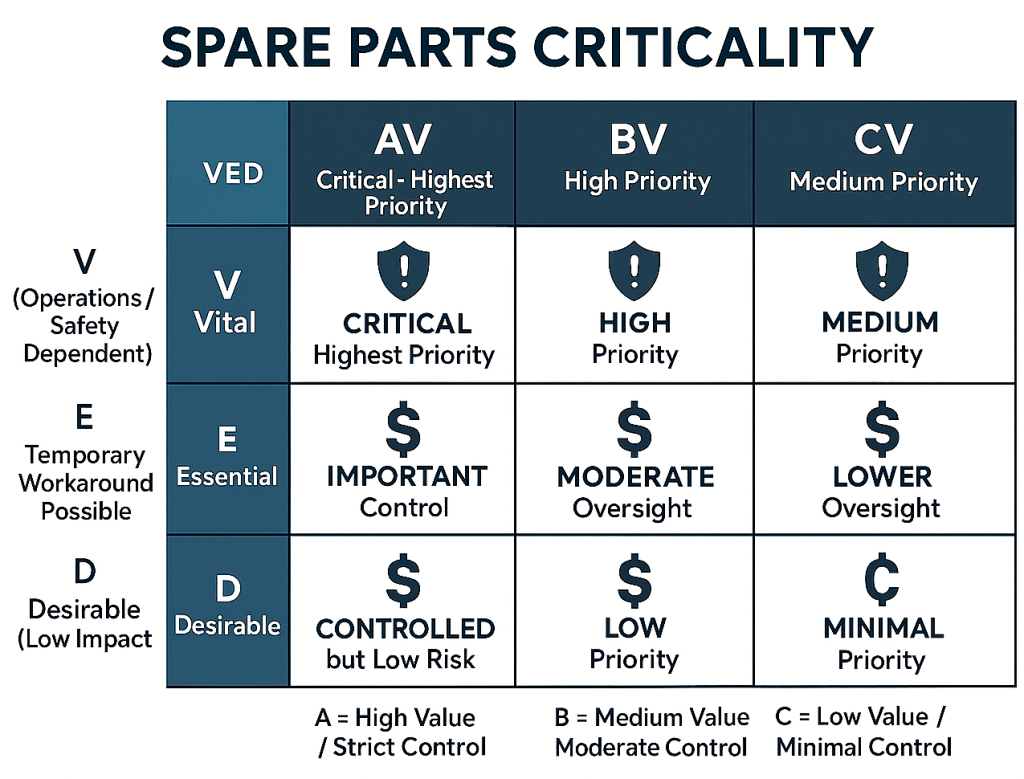

ABC based analysis focus on Part Value/Cost and Operational importance respectively and can be used independently or in combination.

Starting with ABC, the idea here is to prioritize inventory management based on consumption value.

-

ABC Analysis: Based on financial consumption value.

-

A = High-Value, Low Quantity, Close control needed

-

B = Medium-Value, Moderate-quantity. Moderate control

-

C = Low-Value, high-quantity. Minimal control needed.

-

Continuing the same example:

|

Part |

Annual Usage Qty |

Unit Cost ($) |

Annual Consumption Value ($) |

ABC Class |

|

Pump motor bearing |

10 |

500 |

5000 |

A |

|

Conveyor belt sensor |

50 |

50 |

2500 |

B |

|

Lubricant oil |

1000 |

2 |

2000 |

C |

Here, Pump Motor bearing is high-value, “A” class which requires strict control and a safety stock maintained

Lubricant Oil, on the other hand, is low-value, “C” class can be ordered in bulk with minimal monitoring.

While ABC focused on financial impact, VED focuses on operational risk.

Regardless of cost, VED analysis is based on prioritizing spare parts based on criticality to operations.

- V is Vital: Parts or consumables that are essential for production or safety. Cannot run without it.

- E is Essential: Important but temporary workaround is possible

- D is Desirable: Failure has minimal impact on operations

|

Part |

Operational Impact if Failed |

VED Class |

|

Pump motor bearing |

Production stops |

V |

|

Conveyor belt sensor |

Minor delay |

E |

|

Lubricant oil |

Low impact |

D |

Cross-referencing financial importance and operational impact creates a robust spare parts criticality framework.

Practical Applications

-

Optimized Inventory Management

-

Reduces unnecessary holding costs.

-

Minimizes risk of stockouts for vital spares.

-

-

Improved Maintenance Planning

-

Ensures preventive maintenance for high-risk parts.

-

Aligns inventory with maintenance schedules.

-

-

Procurement Strategy

-

Builds resilience with multiple suppliers.

-

Prioritizes contracts for long-lead or high-RPN spares.

-

-

Risk Management & Safety

-

Directly ties into compliance and workforce safety.

-

Reduces unplanned outages and operational risks.

-

Conclusion: Future Outlook

The future of spare parts criticality analysis is moving beyond static classifications. Organizations are shifting toward dynamic criticality assessment, where spare parts are reclassified in real-time based on actual usage patterns, equipment condition, and failure data.

With Verdantis’ AI-powered solutions-including Armonice for data cleansing, Integridad for governance, and Inventory360 for real-time inventory visibility-enterprises can move toward smarter spare parts strategies.

Verdantis AI agents further enhance this by continuously monitoring and reclassifying parts, ensuring proactive decision-making.

This data-driven approach empowers organizations to minimize downtime, reduce costs, improve supply chain resilience, and unlock more intelligent maintenance planning.