The MRO (Maintenance, Repair, and Operations) storeroom, often viewed simply as a warehouse for parts, is in reality the beating heart of an organization’s asset reliability program.

Every misplaced item, untracked issue, and inaccurate record adds friction to operations and cost to maintenance cycles.

For asset-intensive industries like manufacturing, energy, mining, transportation, and utilities, the MRO storeroom is not a backroom function. It is a frontline operational system that directly influences uptime, cost control, and maintenance effectiveness.

What is MRO Storeroom Management?

MRO Storeroom Management refers to the systematic control, storage, and issuance of maintenance, repair, and operating materials that support the upkeep of assets and infrastructure.

It ensures that every spare part or tool required by maintenance personnel is available when needed, in the correct quantity, and in optimal condition.

The core functions of storeroom management are:

- Storing: Safe and organized housing of MRO materials according to criticality, type, and environmental needs.

- Issuing: Controlled dispensing of items based on authorized work orders or maintenance schedules.

- Control: Continuous monitoring of inventory levels, stock movements, and data accuracy through CMMS or ERP systems.

- Strategic Planning: Defining stocking policies, criticality levels, and replenishment methods aligned with maintenance strategies and equipment reliability needs.

- Operational Control: Managing day-to-day tasks such as receiving, putaway, binning, and issuing materials through standardized processes.

- Data Integrity: Maintaining accurate, consistent, and complete materials master data within CMMS or EAM systems.

- Inventory Optimization: Regularly analyzing usage patterns, demand variability, and lead times to ensure optimal stock levels.

- Performance Monitoring: Measuring metrics such as inventory accuracy, fill rates, service levels, and obsolete stock ratios.

MRO inventories are unique. Demand patterns are often irregular, some items may be used daily, while others sit unused for years until a critical breakdown occurs.

This low-volume, high-value nature requires balancing cost containment with reliability assurance.

The Role of MRO Storeroom Management

An MRO storeroom is the controlled facility where maintenance and repair materials, spare parts, and consumables are received, stored, and issued.

Its function extends far beyond physical storage, it ensures that the right parts are available at the right time to keep production equipment operational.

Downtime caused by the unavailability of critical parts can cost thousands of dollars per hour, making storeroom accuracy and efficiency vital to reliability-centered maintenance strategies.

A survey by ABB revealed that

Unplanned downtime costs companies approximately $125,000 per hour. Despite this, over two-thirds of industrial businesses experience unplanned outages at least once a month

In most organizations, MRO materials represent 10–15% of total inventory value but account for more than 50% of stock-keeping units (SKUs).

Unavailable parts extend repair times; overstocked and obsolete items tie up capital and warehouse space. The MRO storeroom thus serves as the operational bridge between maintenance planning and execution, linking supply chain discipline with asset performance.

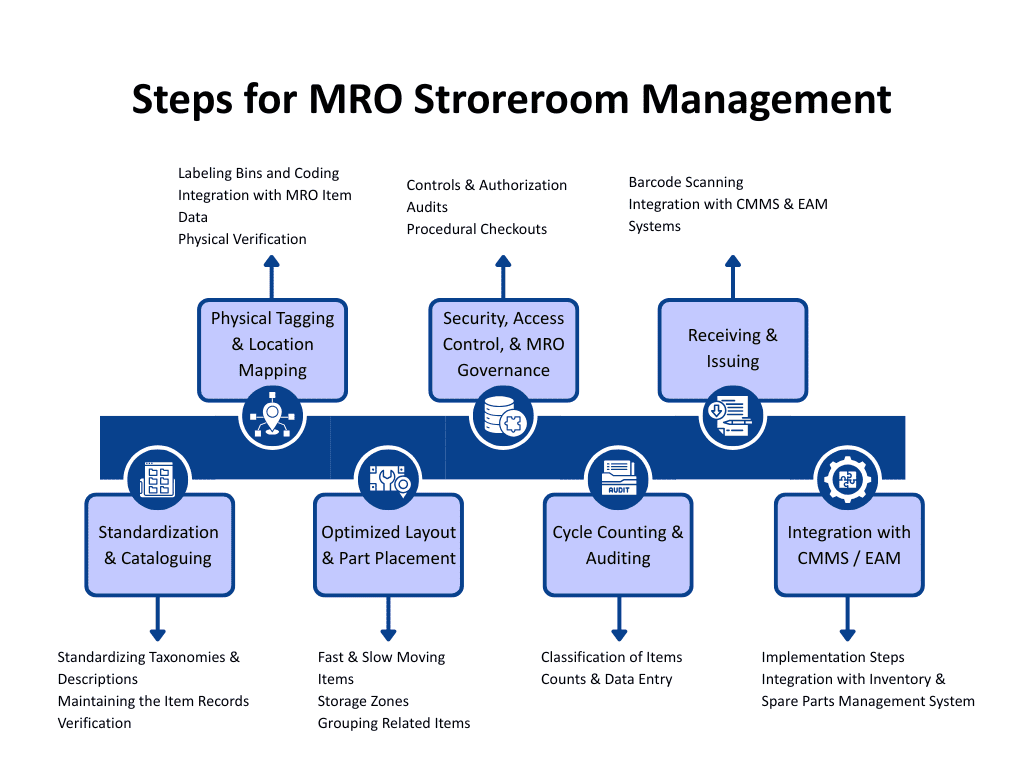

Steps for MRO Stroreroom Management

Standardization and Cataloguing

Structured MRO cataloguing begins with creating standardized records for every part in the storeroom. The goal is to ensure that each part has a single, unambiguous identity.

Step-by-step execution:

1. Define a Standard Taxonomy:

Use an MRO taxonomy as the rulebook for naming. Categorize parts by type (electrical, mechanical, consumable), function, size, and technical attributes. For example, all AC motors could be listed under Electrical > Motor > AC.

2. Create Unique Item Records:

For each part, create an MRO item master data record in the CMMS or ERP system. Include attributes such as manufacturer, part number, voltage, horsepower, and packaging unit.

3. Standardize Descriptions:

Avoid duplicate or ambiguous entries. For example:

Incorrect: “Motor, AC, 50 HP” and “50 Horsepower AC Motor”

Corrected: “Motor, AC, 50 HP, 3-Phase, 415V, TEFC”

Standardized names prevent duplicate ordering, reduce confusion, and enable accurate reporting.

4. Verify and Update:

Conduct a short audit to confirm that each record matches the physical part, updating any discrepancies immediately.

Physical Tagging and Location Mapping

A catalog is only effective if each part can be found quickly in the storeroom. Frequently used items should be positioned near issue counters, while heavy or oversized components require floor-level or mechanical-handling zones.

Environmental controls such as humidity regulation, temperature stability, and corrosion prevention further protect asset longevity, especially for electrical and precision components.

Execution steps:

1. Label Bins Clearly:

Use durable labels with high-contrast printing. Include the part number, description, and bin code. For example:

Aisle 3, Rack B, Shelf 4 – Motor, AC, 50 HP.

2. Create Bin Location Codes:

Assign every shelf, rack, and bin a unique code in the CMMS. This becomes the reference point for both receiving and issuing parts.

3. Integrate with MRO Item Master Data:

Each item record should contain its bin code. This ensures staff always know the exact storage location without searching.

4. Physical Verification:

Conduct a walkthrough to confirm that every label is visible, legible, and matches the CMMS record. Update immediately if there are any mismatches.

Optimized Layout and Part Placement

The physical arrangement of the storeroom determines efficiency and reduces handling time.

Execution steps:

1. Identify Fast-Movers and Slow-Movers: Place frequently used items near the counter or issuing area. Reserve higher shelves for rarely used parts.

2. Define Storage Zones:

- Primary Storage: Active spares.

- Staging Areas: Parts pulled for upcoming jobs.

- Kitting Zones: Complete job packages.

- Quarantine: Damaged, returned, or obsolete items.

3. Group Related Items: Keep bearings with seals, belts with pulleys, and consumables with related tools.

Security, Access Control, and MRO Governance

Uncontrolled access can lead to part loss, theft, or misuse. Implement MRO governance with strict protocols.

Execution steps:

1. Controlled Access Points: Use lockable cabinets, cages, or restricted storeroom doors. Limit access to authorized personnel only.

2. Authorization Records: Maintain a list of staff approved to issue or receive parts. Update this regularly based on role changes.

3. Checkout Procedures: Require staff to sign out items, noting the quantity, work order, and purpose. This information is entered into the CMMS for real-time tracking.

4. Audit Trails: Conduct regular checks comparing issued parts with usage records. Investigate discrepancies immediately.

Cycle Counting and Auditing

Unlike annual physical inventories, cycle counting involves regular, systematic verification of a subset of inventory throughout the year.

It maintains continuous accuracy, minimizes disruption, and identifies root causes of variances in real time.

For high-volume storerooms, a risk-based cycle count that focuses on critical and high-value items, is the most effective control mechanism.

1. Frequency Based on Classification:

- A items (critical/high-value): Monthly

- B items: Quarterly

- C items: Annually

2. Daily Counts: Count a set of items each day during regular shifts.

3. Data Entry and Reconciliation: Enter counts into CMMS immediately. Investigate discrepancies to uncover mis-issues, unrecorded returns, or tagging errors.

Example: A mining site cut inventory write-offs by 70% by switching to cycle counts tied to daily transactions.

Receiving and Issuing

The storeroom must enforce strict material movement protocols. Every issuance must be tied to a valid work order for cost tracking, while receipts must undergo verification against purchase orders for accuracy and quality.

Barcode or RFID systems streamline this process, ensuring that all transactions including receipts, returns, and adjustments are reflected in real time within the CMMS/EAM system.

Integration with CMMS/EAM

Without integration, physical accuracy is meaningless. Phantom or invisible inventory undermines planning and maintenance execution.

How to implement:

Issues: Each checkout updates CMMS, charges the work order, and triggers reorder checks.

Receipts: Scanned into CMMS, updating quantity, bin location, and cost.

Reservations: Planners reserve parts for scheduled jobs.

Reorders: Min/max thresholds trigger automatic purchase requisitions.

Example: A utility integrated barcode scanners with EAM. Accuracy reached 98%, and outage kits were always complete.

Physical and digital inventories are synchronized, supporting proactive maintenance and inventory optimization.

Integrating Spare Parts and Inventory Optimization into Storeroom Operations

Once data integrity and record accuracy are established, the next step is balancing part availability with cost efficiency.

The objective is to minimize carrying costs without increasing the risk of stockouts that extend downtime.

Part Classification and Stocking Strategy

ABC Analysis is a cornerstone of MRO inventory optimization. It categorizes items based on value and consumption frequency:

- A-Class: High-value, low-quantity items (e.g., turbine blades, specialized sensors) requiring strict control and frequent cycle counts.

- B-Class: Moderate-value, medium-frequency items needing periodic review.

- C-Class: Low-value, high-usage items (e.g., bolts, gaskets) managed with bulk controls or bin replenishment.

For example, a $15,000 gearbox motor (A-class) might be stocked in limited quantity with strict reorder triggers, while a $0.50 washer (C-class) can be bulk-stocked to avoid frequent ordering.

This structured classification ensures resources are focused where financial and operational risks are highest.

Dynamic Min/Max Levels and Reorder Points should be calculated using data-driven parameters like historical usage, equipment criticality, and supplier lead times.

Advanced CMMS systems can automate these thresholds, adjusting reorder points as consumption trends evolve.

Proactive Planning & Obsolescence Management

Optimization is not only about stocking; it’s about anticipating needs. By analyzing preventive and predictive maintenance schedules, organizations can forecast spare parts demand with greater precision.

For example, if a compressor overhaul is scheduled every 3,000 hours, associated parts can be pre-ordered to align with maintenance cycles.

Each spare should be linked to its parent equipment through a BOM hierarchy in the CMMS or EAM. This linkage enables planners to identify required parts automatically during maintenance scheduling.

Dealing with Slow-Moving and Obsolete (SLOB) stock is another essential aspect. Parts that have not moved for over two years often tie up valuable capital and storage space. A practical rule of thumb is to classify items as obsolete after 24–36 months of inactivity unless linked to critical or legacy equipment.

These can be reviewed for return to suppliers, liquidation, or repurposing (e.g., cannibalizing usable components). Effective SLOB management can recover significant working capital while freeing up space for active items.

Materials and Spare Parts Data Management

No storeroom can operate efficiently without accurate and standardized data. Materials and spare parts data management is the foundation upon which all storeroom processes are built.

Poor data quality with duplicate records, inconsistent naming, missing specifications, or obsolete part numbers, leads to systemic inefficiencies across maintenance, procurement, and inventory control.

Data deficiencies cascade into costly consequences like:

- Stockouts occur when required parts exist but cannot be found or identified correctly.

- Overstocking arises when inaccurate data hides slow-moving or duplicate items.

- Procurement delays stem from incomplete or ambiguous specifications.

- Maintenance inefficiency results when technicians spend time searching for the correct parts.

Establishing a strong master data governance framework ensures that every storeroom transaction, receipt, issue, reorder, or disposal, is based on reliable and actionable data.

Conclusion

The modern MRO storeroom is far more than a supply room, it is a strategic control point for reliability, cost efficiency, and operational resilience.

By combining disciplined processes, clean and governed data, and data-driven optimization methods, organizations can transform storerooms from cost centers into strategic enablers of uptime.

As industries advance toward predictive and condition-based maintenance models, the storeroom’s role becomes even more pivotal.

A predictive maintenance plan is only as effective as its ability to access the right part at the right moment. Hence, the MRO storeroom stands not at the periphery but at the core of asset reliability management.

Organizations that elevate storeroom management to a strategic discipline supported by accurate data, integrated CMMS/EAM systems, and continuous improvement to achieve measurable gains in uptime, maintenance productivity, and cost performance.