Data fuels every modern enterprise, but not all data delivers equal value. At the core lies master data, which includes customers, suppliers, materials, equipment, locations, and financial structures.

This foundational information connects processes across functions such as finance, procurement, manufacturing, and asset management.

When master data is incomplete, duplicated, or inconsistent, it disrupts operations, inflates costs, and weakens decision-making.

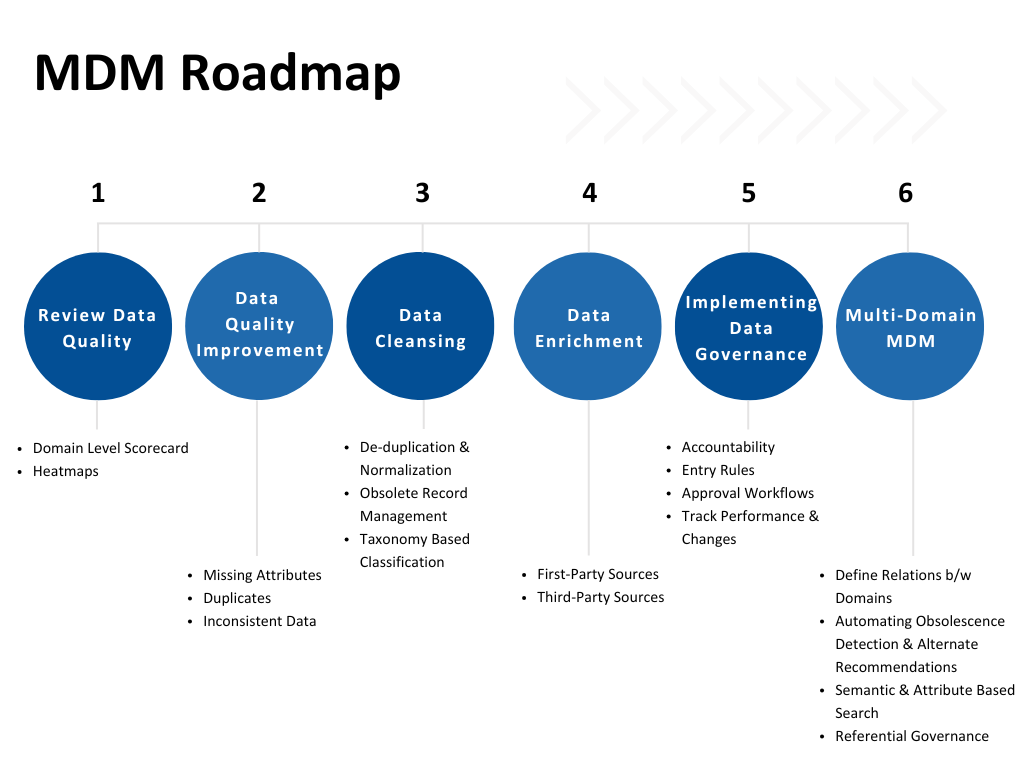

A Master Data Management (MDM) roadmap provides a clear plan to address these challenges. By implementing strategies for master data management across enterprise operations, organizations can convert scattered and inconsistent records into a trusted, governed data source that improves decision-making and operational efficiency.

Building A Strong Implementation Plan

A strong MDM roadmap isn’t just a list of tasks; it’s a cohesive journey from broken data to synchronized reliability. Here’s how each step unfolds in practice:

Step 1: Review Data Quality Across Multiple Domains

Begin by profiling each master data domain such as customer, supplier, material or product, equipment or asset, and location.

Assess quality indicators like duplicate counts, completeness percentages, format errors, and hierarchy inconsistencies.

This is not just about finding errors in records. It is about mapping data blind spots to business impact.

For instance, duplicate spare part records may inflate stock levels and slow down maintenance. Missing supplier attributes can delay purchase orders, while incorrect asset hierarchies may lead to ineffective preventive maintenance scheduling.

Verdantis supports below data domains, allowing enterprises to evaluate both operational and strategic areas for risks and readiness.

Deliverables at this stage include:

Domain-Level Scorecards

Shows measurable indicators like duplicate rates, completeness percentages, and error counts for each master data domain, giving teams a factual baseline.

Heatmaps

Visually connects poor-quality data to the business processes they disrupt, helping stakeholders quickly see where issues like duplicates or missing fields create operational bottlenecks.

Step 2: Identify Key Areas of Quality Improvement

With clear baselines in place, the focus shifts to translating data problems into measurable business impact.

Raw indicators like duplicates, missing attributes, or inconsistent codes only tell part of the story. What leadership needs is a direct connection between poor data quality and operational or financial outcomes.

For instance:

Duplicate material records do not just clutter the master file. They artificially inflate inventory, drive up carrying costs, and complicate procurement planning.

Slow spare parts lookups extend mean time to repair, increasing equipment downtime and lost production hours.

Incomplete customer or supplier data leads to invoice disputes, delayed payments, strained relationships, and missed early-payment discounts.

By quantifying these impacts in terms of cost, time, or risk, organizations can clearly see which domains demand urgent attention.

Below is a video showcasing how Verdantis helps in identifying and removing duplicates.

Studies show that better inventory and predictive maintenance strategies can reduce spare parts holdings by 15–25%

Step 3: Legacy Data Cleansing

Cleansing is the process of eliminating duplicates, fixing inconsistencies, and retiring obsolete records so that master data becomes a single source of truth.

This goes beyond simply deleting duplicates; it requires applying structured rules, taxonomies, and validation techniques to ensure accuracy and traceability.

How cleansing is done:

Duplicate Detection

Use domain-specific match rules (e.g., material number + supplier + description) to identify records that appear multiple times across plants, warehouses, or systems.

Normalization

Standardize units of measure, naming conventions, and attribute formats (for example, “kg” vs. “kilogram”) to ensure comparability across the enterprise.

Obsolete Record Management

Retire or archive discontinued items while preserving an audit trail for compliance.

Taxonomy Based Classification

Apply global standards like UNSPSC (United Nations Standard Products and Services Code) or industry-specific taxonomies to systematically categorize materials, spare parts, and products.

This not only removes ambiguity but also makes future searches, procurement, and reporting more accurate.

Cleansing ensures that organizations are not carrying the burden of inaccurate or redundant records into later stages of their MDM journey.

It sets the foundation for enrichment, governance, and multi-domain management.

Step 4: Legacy Data Enrichment

Enrichment turns a static, minimal record into a robust information asset that actively supports decision-making in planning, sourcing, and maintenance.

Data enrichment is carried out by combining first-party and third-party sources. First-party enrichment pulls data from within the enterprise.

For example, extracting missing supplier payment terms from ERP contracts, pulling equipment installation dates from maintenance logs, or linking spare part criticality from reliability engineering records.

This ensures that master data reflects what is already known across the organization but has never been consolidated in one place.

Third-party enrichment supplements these internal gaps with trusted external datasets, like, manufacturers’ or OEM catalogs can provide part specifications, standardized naming, and cross-reference information.

Commercial databases and regulatory repositories can help verify supplier identifiers, tax IDs, and compliance details.

Material masters can then be enriched with manufacturer part numbers, technical specifications, classification codes, and criticality ratings. Supplier records can be expanded to include lead times, tax identifiers, and complete contact information.

Equipment data can be augmented with functional location hierarchies, maintenance history, and operating parameters.

By blending first-party insights with third-party validation and taxonomy-driven classification, organizations create master data that is not just accurate but also complete, searchable, and business-ready.

Verdantis’ AutoEnrich solution is purpose-built for this, here’s a walkthrough of our solution

Step 5: Implementing a Strong Governance Framework

New errors creep in as records are created or modified, leading organizations back to the same data quality issues they set out to solve.

Governance of master data across enterprise systems ensures that high-quality data is maintained consistently, rather than as a one-time project.

A robust governance system involves:

Define accountability: Assign roles such as data owners, data stewards, and IT integrators to ensure responsibility is clear.

Enforce rules at entry: Apply mandatory fields, uniqueness checks, and standard naming conventions before records are created.

Approval workflows: Route every create or change request through validation and approvals with an audit trail.

Track performance: Monitor stewardship actions against SLAs and escalate violations automatically.

Implementing strong data governance strategies ensures that data quality is preserved continuously, preventing a return to old issues and embedding good practices into daily business operations.

Step 6: Advanced Multi-Domain Data Management

Once foundational quality and governance are in place, the real value of MDM comes from connecting data across multiple data domains.

Instead of working with customer, supplier, material, or asset data in isolation, enterprises benefit from an integrated ecosystem that supports end-to-end processes.

Key practices include:

Defining Relationships Between Domains

Data does not exist in silos. Materials must be tied to suppliers, equipment records must be linked to spare parts, and products must connect to specific sites or customer locations.

Defining these relationships ensures that every business transaction has the right supporting data.

For example, a technician looking at an equipment record can immediately see approved spare parts and their suppliers, or a buyer can trace a raw material back to approved vendors.

Enforcing Referential Integrity Across Systems

Enterprises typically run multiple systems (ERP, EAM, PLM, SCM). If data is updated in one but not synchronized across others, processes break down.

Referential integrity ensures that when a supplier record is updated in ERP, it is also reflected in the asset or procurement systems.

This reduces duplicate work, prevents mismatches, and ensures a “single version of truth” across the enterprise.

Enabling Semantic or Attribute-Based Search

Traditional part lookups depend on knowing an exact ID or catalog code, which is inefficient when those codes are inconsistent or unknown.

With semantic search, technicians and buyers can find items using functional descriptions or attributes (e.g., “pressure valve, 2-inch, stainless steel”).

This reduces wasted time, lowers emergency purchases, and improves inventory utilization.

Automating Obsolescence Detection & Alternate Recommendations

Parts, materials, and even suppliers become obsolete over time, which makes having a reliable enterprise solution for parts obsolescence management in asset-intensive industries essential.

A multi-domain system can automatically flag when an item is discontinued, out of compliance, or no longer preferred. It can then recommend alternates or substitutes already in the catalog.

This avoids downtime, prevents last-minute emergency buys, and supports strategic sourcing.

Verdantis’ SpareSeek solution is purpose-built for this, here’s a walkthrough of our solution

The Risk of Jumping Straight into Tools

Many organizations rush into MDM by purchasing software or running isolated clean-up projects. These tool-first efforts often stall because the bigger picture is missing.

Without clear priorities and ownership, teams focus on fixing whatever is easiest rather than what delivers the most value. Data that looks clean today quickly decays without governance workflows in place.

Integrations add to the complexity: one system may show a supplier as active while another lists the same record as inactive, creating conflicting versions of the truth.

Another common risk is failing to connect data domains to the business processes they affect. Not every industry is impacted by poor-quality data in the same way, and investing in the wrong domain first can mean wasted effort and little visible return.

A roadmap prevents this misalignment by showing which domains matter most in each sector and tying them directly to operational impact.

Industry | Key master data domains | Operations most affected by poor quality |

Financial | Customer, Supplier/Vendor, Product (financial instruments, accounts, policies) | Billing and collections errors, duplicate customer records |

Manufacturing | Material, Spare Parts, Bill of Materials (BOM) | Inventory inflation, production delays, wrong units of measure, incorrect alternates or substitutes |

Oil, Gas and Energy | Equipment, Asset, Location, and, Spare Parts | Longer mean time to repair, safety risks, emergency procurement, wrench time loss |

Utilities | Asset & Equipment, Service, and, Location | Field work rework, outage response delays, billing disputes |

Mining | Equipment, Material, and, Supplier | Unplanned downtime, excess spares, procurement leakage |

Chemicals and Process Industries | Material & Equipment | Quality deviations, costly rework |

Retail and Consumer Goods | Product, Customer, Supplier, and, Location | Listing errors, demand planning misses, invoice deductions |

Healthcare Providers | Item Master, Supplier, Asset & Equipment | Procedure delays, supply shortages, cost variance |

Conclusion

A structured Master Data Management approach provides organizations with a clear path to transform fragmented and inconsistent data into trusted, business-ready information.

By systematically assessing data quality, prioritizing critical improvements, cleansing and enriching legacy records, implementing governance, and linking multiple domains, enterprises can enhance operational efficiency, reduce errors, and enable more informed decision-making.

Effective MDM is not just about managing data; it is a strategic capability that drives reliability, compliance, and long-term business value across asset-intensive industries.