In every industry, MRO data (Maintenance, Repair & operations) plays a crucial role in the smooth running of day-to-day activities. These activities can range from very small tasks such as routine equipment check – up to entire plant repair operations for one to two weeks straight.

To assign and keep track of such activities, work orders are issued against each equipment to define the scope, budget, time constraint and responsible party for the operation.

Given such high importance, one would assume that such MRO operations would be very efficient. However, information loss, miscommunication and under optimized processes is quite frequently seen in the entire approach.

In this article, we will explore what exactly is a work order, how a work order is executed (from start to finish), issues with traditional Work order Management and finally how AI is transforming this industry to become more efficient and reliable.

What is a work order?

Whenever a request for maintenance tasks is raised, a work order is issues as a formal request for completing said task.

Work order can be categorized into different categories based on type of work,

Components of a work order must include at least these items:

- Work order / Task description

- Who raised the work order request (Requestor)

- Who is the approving party (Approver)

- To whom the work order is assigned (Assignee)

- Work order priority

- Start and end date for the work order.

Having a strong Work order management system is crucial to ensure smooth operation of maintenance activities, to reduce unnecessary costs and timely repairs of critical equipment.

Types of work order

Based on various factors such as urgency, planning time, equipment type and priority and regulatory requirements, work orders are classified in following different categories.

Work Order Type | Description | Typical Use Cases |

Corrective Maintenance | Generated after a failure or issue is reported | Equipment breakdowns, emergency repairs |

Preventive Maintenance | Scheduled regularly to prevent breakdowns | HVAC filter replacement, routine inspections |

Inspection Work Orders | Focused on safety, compliance, and performance audits | Safety checks, regulatory compliance |

Emergency Work Orders | For urgent issues that pose safety or operational risks | Critical system failures, safety hazards |

Installation or Setup | For deploying new equipment or systems | New equipment commissioning, upgrades |

Calibration or Testing | For quality assurance and compliance | Instrument calibration, performance testing |

Current status of work order

When it comes to Work Order Management, majority of industries still rely on traditional approaches. Some of these include:

- ERP or legacy CMMS solutions

- Manual work order tracking using excel sheets or word documents.

- Work orders written and circulated using papers.

- Email tracking of tasks.

Several problems arise due to scenarios such as:

When it comes to Work Order Management, majority of industries still rely on traditional approaches. Some of these include:

- ERP or legacy CMMS solutions

- Manual work order tracking using excel sheets or word documents.

- Work orders written and circulated using papers.

- Email tracking of tasks.

Reactive Maintenance Culture

- Delayed response times due to manual triaging processes

- Incomplete failure history and cost documentation

- Minimal preventive maintenance strategies

Resource Optimization Issues

- Poor technician routing and scheduling

- Inadequate inventory synchronization with work orders

- Limited integration between operational systems

Analytics and Improvement Gaps

- Insufficient data analysis for continuous improvement

- Missed opportunities for predictive insights

- Lack of actionable intelligence from historical data

Companies have now started to adopt various technological advancements to improve said process:

CMMS (Computerized Maintenance Management Systems) centralize maintenance planning by:

- Automating work order creation and assignment

- Tracking comprehensive asset history and maintenance logs

- Sending proactive alerts for preventive maintenance

- Managing inventory and spare parts efficiently

- Generating detailed compliance reports

ERP Systems (Enterprise Resource Planning) provide broader integration:

- Linking maintenance costs directly to financial systems

- Automating parts procurement from inventory management

- Synchronizing technician availability with HR data

- Aligning maintenance KPIs with strategic business objectives

However, even with these advancements, there are still critical gaps present in the Work order management.

After conducting numerous user interviews and thought market research, we found three key areas in the work order management process where critical gaps are still present:

Missing material information flows from work orders leading to incomplete or inaccurate BOM data.

BOM data is not linked to any equipment or is mismatched.

Lack of automation in the entire work order management process leading to delays and longer downtimes.

To resolve the said issues, Verdantis is deploying agents AI to transform and automate the BOM and Work Order management data processes.

The AI Revolution: Introducing WorkSync

WorkSync is Verdantis’s latest product offering in the series of our AI agents being built to transform the MRO industry one step at a time.

At present, a lot of valuable information like BOM update data, material cost and repair time, equipment failure reason, parts procurement time etc. is lost in work orders.

Root causes for information loss:

- Work orders are not properly updated: Historically there have been numerous changes in the equipment due to which information is lost in work orders or SAP.

- BOM information is missing from some older equipment and was never updated or even extracted from the engineering drawings.

Presence of independent Silos: Some companies have independent silos to handle MRO activities. Sometimes there is a communication gap between the silos and hence there is loss of information there.

Apart from this, the current work order creation process is manual, time-consuming and prone to errors. To resolve both the above-mentioned problems, we have launched our latest AI agent called WorkSync.

Solution 1: BOM Update

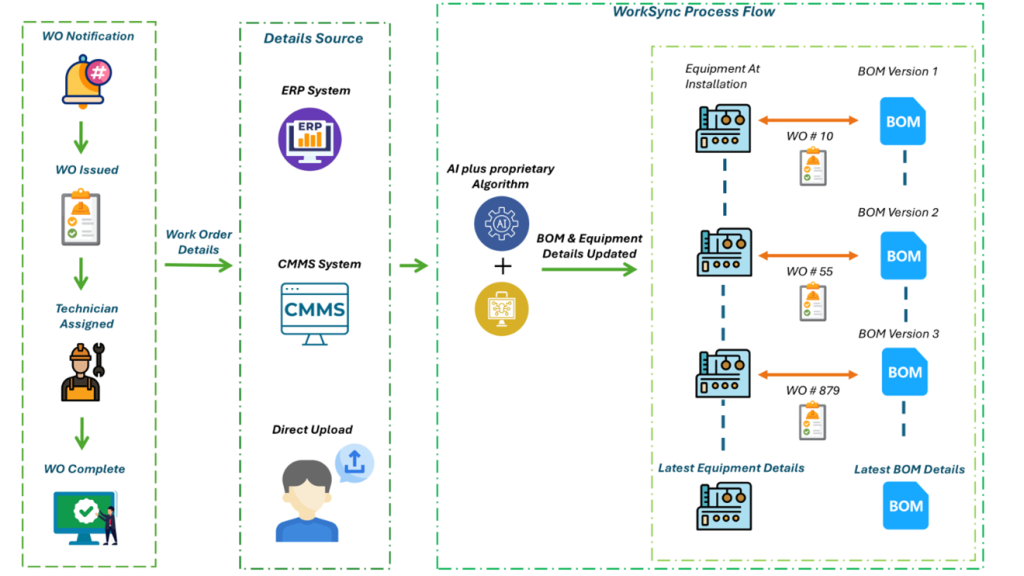

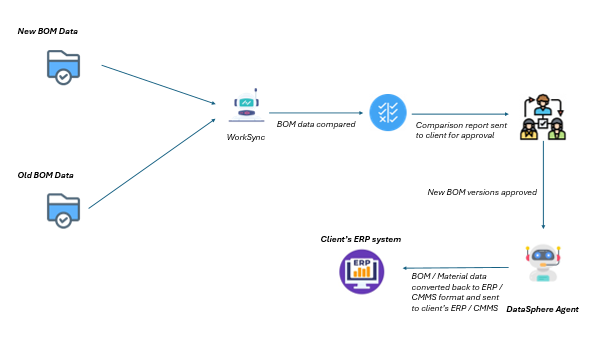

WorkSync uses AI to extract the BOM details from Work orders, long text in notifications and goods movement data. It provides actionable insights about missing BOM data and linkages to the end user.

Once approval is received from client, it also updates BOM data directly in the ERP or CMMS system after getting approval from the client

Let’s take a closer look at the BOM Update process flow for WorkSync:

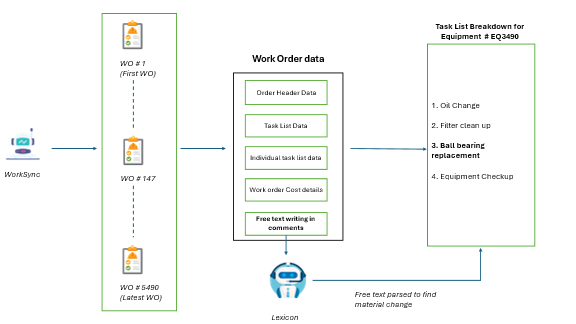

Step 1: WorkSync automatically extract and parse work order information for all the equipment’s installed at your plant / site.

Step 2: Any part replacement leading to material code / spart part # change is mapped against a specific equipment (Please refer to Image 3 for detailed view). Any free text present in the work order is also parsed to capture material change information.

Necessary details like BOM data updates, repair cost and time etc. are also parsed from the task details.

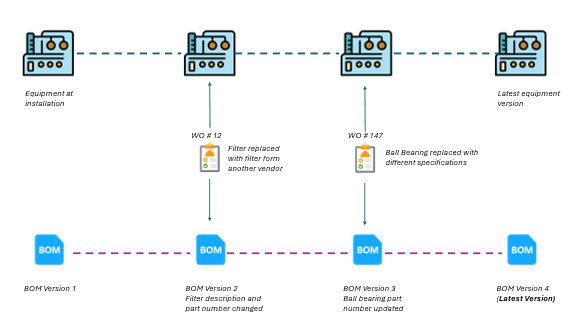

Step 3: A chronological timeline of each piece of equipment history is built (from installation to present time) including BOM versions reflecting changes in BOM data over time.

Step 4: For BOM data, updated BOM versions are created and sent for approval (to be later merged into the ERP system.

Solution 2: Automatic work order creation and assignment

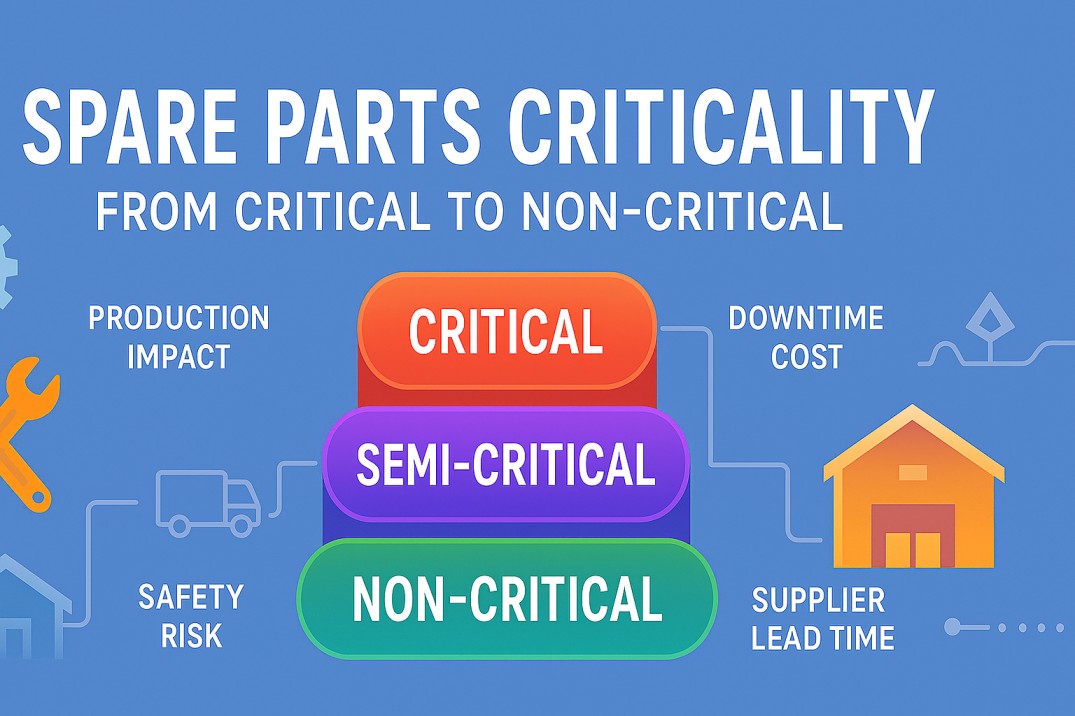

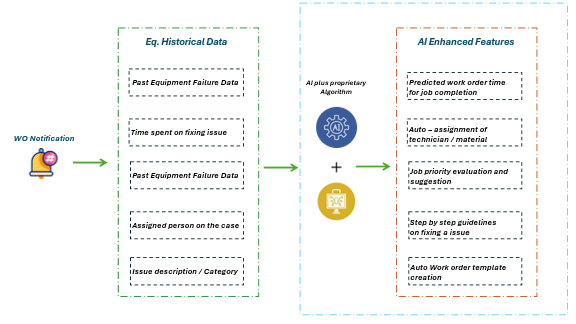

WorkSync leverages AI to analyze past historical work order data, asset criticality data, and notifications data to automatically create schedule and track work orders.

Apart from this, WorkSync help users with asset data management, inventory optimization, work order prioritization and resource allocation.

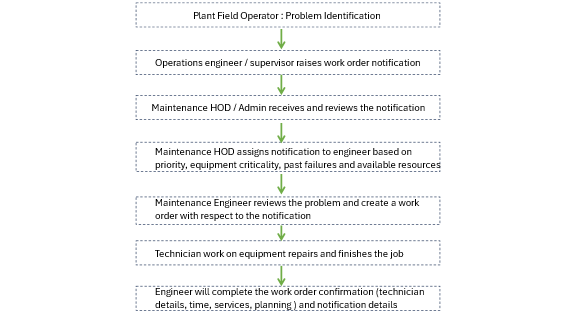

To understand how work orders are created and managed in a typical MRO space.

Using an AI driven product like WorkSync has these major benefits over traditional work order management processes:

AI driven instant work order creation: Just after receiving notification from either the operations engineer or supervisor, WorkSync will analyze the notifications information, equipment historical data (failure reassures, frequency, priority, work order completion time and criticality) to instantly generate work order.

Maintenance HOD or admin can review, edit and approve multiple work orders in one go instead of spending hours analyzing all relevant information and creating the work order.

Automated extraction and scheduling of preventive / scheduled work orders: It is quite a hassle right to manually extract and create preventative maintenance schedule for newer equipment in your plant. Also, since it is a manual process, it is highly prone to error or scheduling conflicts.

In WorkSync, users have the option to directly upload equipment manual / catalogue or OEM guideline text. Once uploaded, it will extract and schedule preventative maintenance automatically (after receiving approval from the user) without any difficulties.

Auto prioritization for Work Orders: WorkSync has a AI driven architecture where work orders are prioritized based on past historical data, issue priority level, equipment criticality analysis and available resources.

Equipment repair instructions: WorkSync can provide step by step detailed instructions for equipment repair based on past issues, repair techniques and equipment manual / catalogue / OEM guidelines.

Work order tracking and Customization: WorkSync provides multiple options for maintenance engineers / Department Heads to update / track work orders in progress. Apart from this, user can have customizable end-to-end workflow for the work orders with defined rules for each entity.

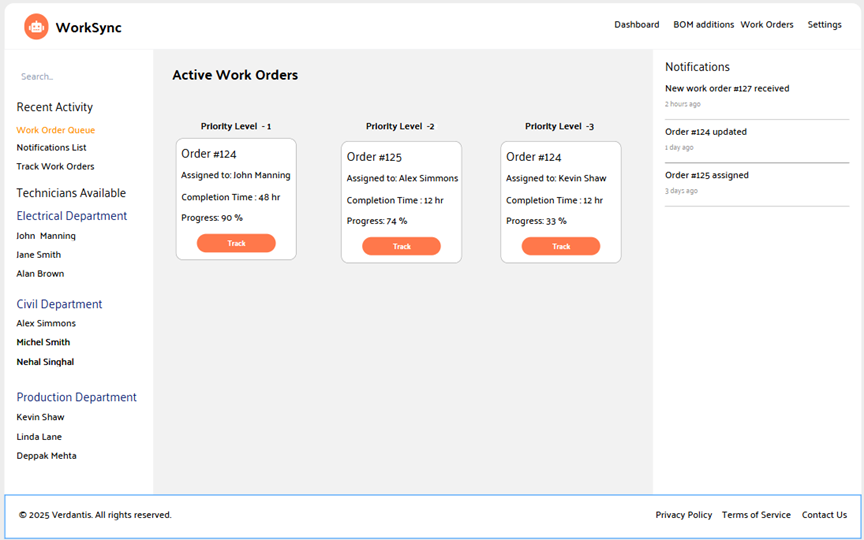

Here is a quick example of the WorkSync dashboard where user can seamlessly manage and track progress of the work orders generated via AI

Conclusion: Embracing the Intelligent Future

WorkSync integrates seamlessly with other ERP or CMMS solutions and can help users manage their assets and work orders in a much more efficient and automate way.

The transformation of work order management represents more than just technological advancement, it’s a fundamental shift toward intelligent, data-driven maintenance operations.

Organizations that embrace AI-enhanced solutions like WorkSync position themselves to:

Maximize Asset Value: Through optimized maintenance strategies and extended equipment lifecycles

Minimize Operational Risk: Via predictive insights and proactive maintenance approaches

Enhance Competitive Advantage: Through improved efficiency, reduced costs, and superior asset performance

Work orders are evolving from static documents to dynamic, intelligent tools that drive operational excellence. By understanding current limitations, embracing AI-powered solutions, and implementing comprehensive transformation strategies, organizations can achieve unprecedented levels of maintenance efficiency and effectiveness.

The future of work order management is not just digitality’s intelligent, predictive, and transformative. Organizations that act now to implement these advanced capabilities will lead their industries in operational excellence and competitive advantage.

Ready to transform your work order management with AI? Discover how WorkSync can revolutionize your MRO operations and unlock the full potential of intelligent maintenance management.