In this article, we cover the genesis of material data management, the various types, challenges and how organizations can build excellence with data-management strategies across production, maintenance (MRO), raw material management and more.

The term “Materials Master” can trace its roots all the way back to 1970s and 1980s when SAP Introduced the term to refer to a central repository that stored all materials-related information.

The concept of Master Data itself comes from a data base management terminology, referring to all core, non-transactional data that provides context for business operations.

The Material Master is a standard object in SAP modules like MM (Materials Management) and PP (Production Planning)

The same concept also exists in other ERPs but under different names, “Materials Master” object, for example, is called “Item Master” in Oracle Systems.

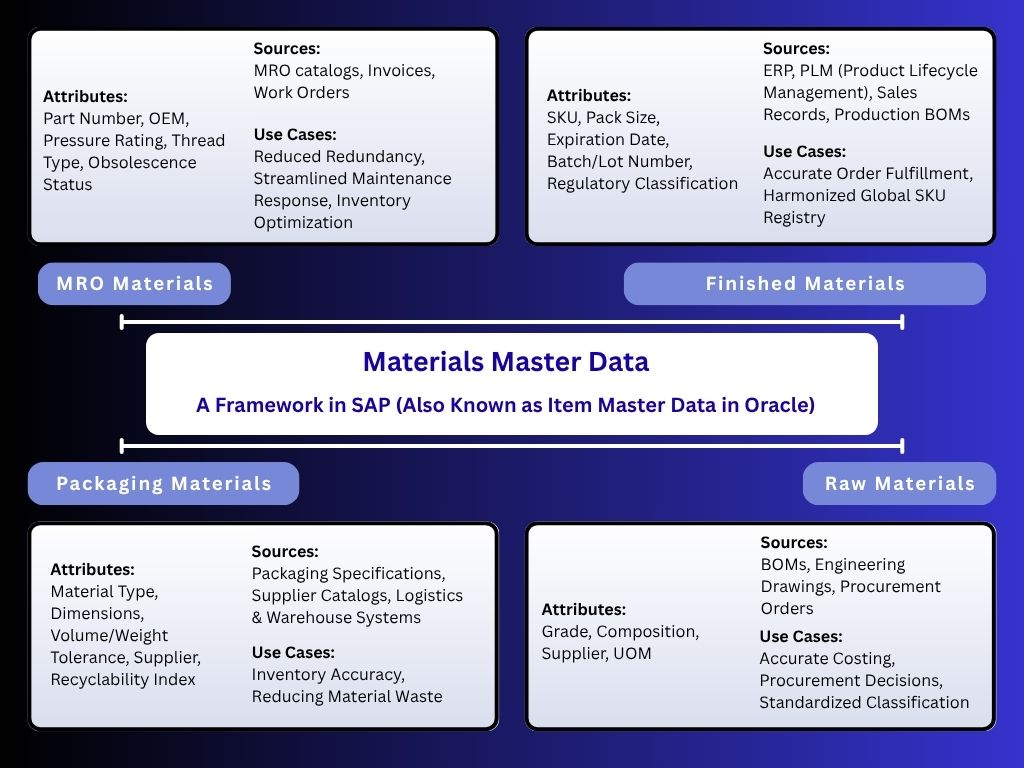

A Materials Master is the core dataset that is used to describe movable “material items” from raw materials, finished goods, spare parts and other materials used in in daily business operations.

Naturally, as business processes scale, the data quality within a materials master erodes and requires correction for smoother business operations. Moreover, governance systems are needed to ensure the data-quality remains intact in a steady state.

Materials Data Management is critical in industries like manufacturing, utilities, energy, and mining where even slight issues with data quality tend to have a detrimental impact in procurement costs, maintenance management and day-to-day perations.

Categories within Materials Master

In any organization, materials master isn’t just one big dataset referring to all types of materials that are in-use.

Instead, it is segmented into different categories, each serving a different function and each requiring some tweaking as far as managing their data is concerned.

MRO Materials Master

Arguably, managing MRO materials data quality is one of the more tricky and important aspects within Materials Management as a discipline.

MRO simply translates to “Maintenance, Repairs & Operations” and MRO materials refers to spare parts, replacement parts and consumables that are used in large-scale production operations.

In general, maintenance-specific functions aren’t governed by solid data management protocols, so they are prone to errors.

Moreover, the nature of the data can be technical and not easily available, making its management even trickier.

The industries where this is a crippling issue are also those where their data capabilities are ranked among the lowest, compounding the issue even further.

Common Challenges with MRO Materials Master

Duplication in Data

By far, one of the most challenging issues when it comes to managing MRO spare parts data.

Due to urgent, last-minute procurement requests and a total absence of data management protocols and technology to support it, the same part record is created in the system multiple times over.

While this may seem trivial, duplicate entries directly inflate procurement MRO spends by holding the same inventory part multiple times over.

For Example:

A single 3-pole electrical contactor could appear as:

“Contactor, 3P, 24VDC Coil, 32A”

“3 Pole Contactor 32 Amp 24V DC”

“3P Contactor 3RT2026-1BB40”

“Contactor 3RT2026-1BB40”

These descriptions all refer to the same product, but inconsistent formatting, missing brand info, or rearranged attributes lead to multiple material codes.

Here is a walkthrough of how Verdantis’ AI agent deduplicates the data, and flags L2 and L3 duplicates (de-duplication starts at 11:42):

As reported by Forbes in a study on duplicate enterprise data:

A Fortune 200 oil & gas company uncovered $37 million worth of duplicate parts in its global inventory. The duplicates went unnoticed by both the company and its suppliers, leading to inflated carrying costs (15–20% above part value), wasted warehouse space, possible tax implications, and reduced profitability.

These issues arise when the front-line worker or procurement executive makes a request to purchase a given part without updating the specifications, measurements and other part-related details in the system.

Left unmonitored, this issue can compound many times over, resulting in an unreliable material master view that doesn’t inform procurement or supply chain teams adequately.

In severe cases, especially where inventory management of spare parts is not built on solid foundations, this results in material stockouts, that can spiral into equipment downtime, resulting in production halts till the procurement of said spare part is completed.

For Example:

At a plant site, a pump motor might be entered into the system with limited or inconsistent details:

Entry 1: “Motor”

Entry 2: “Pump Motor 15HP”

Entry 3: “Motor for Pump – No Spec”

In this case, key information such as voltage, RPM, manufacturer, model number, or frame size is either missing or partially recorded.

This lack of complete data can delay maintenance, hinder accurate sourcing, and create confusion across departments, ultimately impacting equipment uptime and operational efficiency.

According to an article published by Harvard Business Review, "47% of newly created data records contain at least one critical error, and only 3% of company data meets basic quality standards, even under the loosest criteria - highlighting the urgent need for effective data enrichment and governance."

Inconsistent Data

Data records in a materials master generally follow a fixed standard based on a pre-defined taxonomy. For example, UNSPC is one such globally defined taxonomy that classifies products, and defines their data fields based on the category

Data pertaining to the same spare part, written in different formats, order, with or without abbreviations; can cause discrepancies in the materials dataset.

Even a single spare part, if represented inconsistently across different records, can disrupt procurement accuracy, increase inventory costs, and lead to maintenance delays.

Below is an example of how inconsistent naming conventions and formats lead to confusion across systems:

The entry of a Hex Bolt might appear in a materials master as:

Entry A:

Bolt, Hex, M12x75, SS316, FTEntry B:

Hex Bolt M12 75mm Stainless Steel Fully ThreadedEntry C:

BOLT HEX HD M12*75MM SS-316 FTEntry D:

Hexagon Head Bolt M12x75 A4-316

Inconsistent formatting, use of abbreviations (like “FT” or “SS316”), and varied unit or material representations (e.g., “75mm” vs. “75”, “SS316” vs. “A4-316”) often cause the same part to be treated as multiple distinct entries in the system.

This leads to duplicate inventory, missed bulk procurement opportunities, and delays in maintenance due to uncertainty over part specifications.

Standardized taxonomies and uniform data entry are essential to avoid such inefficiencies and ensure reliable, actionable material master data.

Here is a walkthrough of how Verdantis’ AI agent standardizes and as per the taxonomies:

As per a report by PW Consulting, “Companies can reduce unplanned downtime by upto 23% after standardizing MRO part description and attributes, demonstrating the impact of clean data”

Challenges with MRO Material Governance

The above-mentioned challenges are the effect of poor-quality data management and the consequences of the same.

Correcting legacy data-quality issues is a one-time activity and it can be remedied with a data cleansing exercise.

However, this does not solve for on-going data quality concerns, meaning the materials data is likely to get compromised over a certain period again.

Solving for this requires a top-down revision in the organization’s approach to data governance for MRO.

Yes, modern technology, like our own purpose-built MRO governance solution, Integrity, can help by doing much of the heavy lifting with industry-trained AI models but this also requires a change in processes, approval systems and a renewed approach to data management processes and rarely works in isolation.

Here is a video of how our MRO Materials Governance product

Seamless materials management also requires data to be synchronized across different master data objects. MRO materials spares, for example, need to be synchronized with equipment or asset master data.

This should ideally be done at the time of creation itself, but can be done for legacy materials with the help of a digital BOM, for which, seamless management of digital bill of materials for fixed assets is a necessary pre-requisite.

Effective materials master data management requires keeping the database free of outdated or inactive records.

Obsolete data refers to material records that are no longer relevant, and are often tied to phased-out equipment, discontinued parts, or legacy suppliers.

If left unmanaged, obsolete materials clutter the item master, leading to confusion in procurement, misalignment with actual maintenance needs, and inaccurate reporting. These records can also distort analytics, inflating inventory valuation and skewing consumption trends.

Obsolete parts data should be managed and addressed through regular audits and automated checks that flag materials with no movement history, unlinked asset references, or expired manufacturer information.

Establishing lifecycle statuses within the material master, such as “Active, Inactive, or Obsolete,” helps stakeholders make informed decisions.

In legacy systems, linking material records to current equipment hierarchies or digital BOMs can surface dormant parts, making it easier to cleanse and deprecate them from the active master.

In a case study conducted at a mining logistics center in Chile, researchers evaluated 8,100 spare parts worth approximately €4.1 million and found that around 34% of the items were obsolete or inactive, having seen no movement in over 24 months. These obsolete parts tied up over €1.2 million in working capital and incurred annual carrying costs of 18–22%, amounting to nearly €220,000–€264,000 in avoidable expenses. The absence of visibility into end-of-life phases led to poor inventory decisions and inflated lifecycle costs.

The Case for Investing in MRO Materials Master

The value that asset-intensive organizations can unlock by addressing these data-quality challenges in their MRO materials master is significant, measurable and the statistics for the same also make a strong case for correcting the processes and quality in them.

Some of these are:

A measurable decrease in Procurement Costs

With a clean, standardized materials master, organizations gain better visibility into part usage, consumption trends, and duplication across sites.

This enables consolidated purchasing, optimized vendor negotiations, and reduction in overstocking or emergency buys, resulting in a clear drop in overall procurement spend.

Fewer instances in production downtime

Poor-quality MRO data often results in incorrect part orders or delays in identifying the right spares – leading to avoidable equipment downtime.

A reliable materials master ensures that the right part is always sourced on time, reducing unplanned outages and improving asset availability.

Elimination of Manual Processes

Data inconsistencies typically force maintenance and procurement teams to spend hours manually verifying part specs, checking with suppliers, or validating older orders.

A governed MRO dataset automates these checks, eliminating repetitive manual tasks and improving operational efficiency.

Reliable Automations in MRO Procurement

Automated workflows, reorder alerts, and predictive stocking models rely heavily on the accuracy of materials master data.

By ensuring consistent, enriched data, organizations can confidently enable digital procurement tools and automated processes, without the risk of ordering the wrong part.

Beyond Standard MRO Materials Data Management

Several software solutions that solve for master data management in ERP systems already exist today that solve for standard use-cases in MRO materials management like L1 deduplication, data validation and categorization

In fact, the ERP solution providers themselves also offer built-in solutions for data management.

For example, MDG by SAP, is a data governance software solution offered by SAP that solves for standard data management challenges in SAP source systems.

Similarly, Oracle Master Data Management is the software offered by Oracle for customers on Oracle ERP.

With that said, most enterprises with large-scale, complex maintenance operations need to solve for data quality and data availability challenges within a short turnaround, accurately.

And purpose-built MRO Master Data Solutions, like the ones offered by Verdantis, are key to solving these challenges.

Many spare part records in the MRO material master are either incomplete or carry limited descriptions.

AI-powered MRO data enrichment for spare parts and materials addresses this challenge by using models trained on millions of validated MRO datasets to intelligently infer and populate missing technical specifications such as thread type, voltage rating, pressure class, or material composition.

This enrichment not only ensures complete and usable data but also enables efficient procurement, accurate classification, and reliable stock identification.

A significant portion of spare part and equipment data exists only within unstructured sources like Bills of Materials (BOMs), OEM datasheets, engineering drawings, and scanned purchase orders.

These documents often contain the only reference to key specifications like voltage, pressure rating, or material grade.

AI-powered document processing can intelligently interpret these files, extract relevant technical attributes with contextual accuracy, and convert them into structured formats. The extracted data is then mapped directly to existing material master records.

The outcome is a unified, enriched view of each item, bridging information gaps and ensuring consistency across procurement, engineering, and inventory systems, all while reducing manual workload and data errors.

Traditional cleansing projects are often manual and time-intensive, involving extensive human effort to identify duplicates, correct classifications, and fill in missing data.

AI-powered platforms can accelerate this process by automatically detecting duplicate records even when formats or naming conventions vary significantly.

The system also uses rules-based and machine learning approaches to cleanse, classify, and enrich tens of thousands of records in a matter of weeks, offering a significantly shorter turnaround time than conventional methods.

Instead of allowing poor-quality data to accumulate and addressing it periodically, modern MRO data platforms enable real-time validation and governance.

As new parts are created or requested, whether via procurement, maintenance, or engineering workflows, the platform checks for duplicates, validates attributes, and suggests standardized descriptions based on predefined taxonomies.

This ensures that clean, structured, and accurate data enters the system from the outset.

In large organizations, MRO data does not exist in isolation. It intersects with supplier data, asset hierarchies, location data, and financial systems.

Purpose-built solutions are designed to integrate with broader enterprise MDM programs, enabling consistency across domains such as supplier, product, location, and asset data.

This integrated approach supports cross-functional visibility, improved decision-making, and better alignment across maintenance, procurement, and finance functions.

Direct Materials Master

The data quality challenges for direct (or raw) materials master are also pretty-much like that of MRO materials, albeit with some minor differences.

Direct Materials master data refers to the data about raw materials, components, or parts that are purchased or produced and are directly used in manufacturing finished goods.

It enables procurement, inventory management, and production planning in SAP/ERP systems.

For Example,

At a plant site, a motor coupling might be entered as:

Entry 1: “Motor Coupling”

Entry 2: “Coupling”

Entry 3: “Drive Coupler”

None of these records include key specifications like bore size, material type, torque rating, or manufacturer, making it difficult to source the correct part when needed.

This incomplete data leads to guesswork, delays, or even part mismatches.

For Example,

In the maintenance system, a stainless steel fastener may be recorded as:

Entry 1: “Bolt SS 316 M10x50mm”

Entry 2: “M10*50 SS Bolt Grade 316”

Entry 3: “Stainless Steel Bolt M10 50mm 316”

These describe the same item, but inconsistent formatting, units, and descriptions clutter the database and result in unnecessary duplicates and procurement confusion.

Challenges specific to duplication, missing data, obsolescence and inconsistent data are pretty much the same as the ones we discussed earlier specific to MRO.

However, a few data management aspects are unique to direct materials master.

- Direct materials are often deeply integrated with production planning systems, and rely heavily on demand forecasting systems to provision for manufacturing activities

- Integrations with product bill of materials also run quite deep and they

- Direct materials often need to meet specific regulatory standards depending on the industry (e.g., quality standards, environmental regulations, safety certifications). Ensuring that material master data reflects this compliance requirements across regions can be challenging

Finished Goods Material Master

Materials pertaining to finished goods, also commonly known as “Product Master Data” data pertains more to finished or semi-finished goods that a company manufactures, sells or distributes.

It includes all attributes and specifications required to;

- Design the product

- Produce it.

- Market it effectively.

- Sell it across channels and regions

- Support it throughout its lifecycle

In ERP systems like SAP, Product Master Data often sits within the Material Master, but when extended to customer-facing processes, it overlaps with Product Information Management (PIM) systems.

For Example,

In a warehouse system, a power drill might be entered as:

Entry 1: “Cordless Drill”

Entry 2: “Drill, 18V”

Entry 3: “Power Tool”

Critical information like brand, model number, battery type, and chuck size is missing.

This lack of detail makes it difficult to identify, reorder, or recommend compatible accessories.

For Example,

A finished electric motor product might show up as:

Entry 1: “3 Phase Induction Motor 7.5kW”

Entry 2: “7.5 kW 3Ph Motor”

Entry 3: “Motor, Electric, 3PH, 10HP”

Different naming conventions for the same product create redundancy and reduce data usability for inventory, sales, or service operations.

Challenges specific to Finished Goods Materials Data

- Complex product variants and configurations

Managing multiple versions of a product based on size, color, features, or customer-specific requirements often leads to inconsistent representation across systems. - Inconsistent naming conventions and descriptions

Variability in how products are described across plants, teams, or regions affects search accuracy, reporting quality, and alignment between sales and operations. - Missing or poor-quality enrichment data

Many finished goods records lack essential details like images, specifications, compliance labels, or marketing copy, which impairs digital commerce and downstream processes. - Channel and region-specific variations

Different sales channels and geographic markets often require localized product attributes, regulatory data, and packaging details, making uniformity a challenge. - Duplicate product records

Slight variations in SKU codes, descriptions, or categorization often result in duplicate entries, inflating inventory and affecting demand forecasting and pricing accuracy.

Packaging Materials Master

Packaging Materials master is exactly what it sounds like, a master dataset within SAP MM that contains all the data pertaining to packaging materials used for the final product.

Naturally, this is a dataset that is put-to-use only by manufacturing enterprises with large production operations.

Challenges specific to Managing Packaging Materials Master

- Complexity of Data Attributes: Packaging materials often have more complex data requirements than direct materials, as they typically involve multiple attributes like size, shape, weight, material composition (e.g., cardboard, plastic, glass), environmental considerations (e.g., recyclability), and compliance with regulations (e.g., food-safe or tamper-evident features).

- Multiple Suppliers & Sourcing Strategies: Mismanagement or lack of consistency in tracking which supplier provides which packaging, and under what terms, can lead to procurement inefficiencies and misalignment in inventory. It can also lead to sourcing delays if packaging suppliers do not meet required standards.

- Integrations with other master data systems: Packaging materials data is often siloed from other material master data systems (such as for raw materials or finished goods) due to differences in their roles and the stakeholders who manage them. Integrating this data with procurement, inventory, and logistics systems is a common challenge.

- Managing Units of Measure: Packaging materials are often measured in different units, like boxes, rolls, sheets, pallets, etc. Managing these multiple units of measure and ensuring that they align with procurement and inventory systems can be a challenge.

- Data Pertaining to Environment Sustainability: Industries are under increasing pressure to reduce packaging waste and adopt more sustainable materials. Packaging materials master data needs to reflect these sustainability considerations and track material recyclability, carbon footprint, and waste disposal options.

Core Pain Points in Materials Master Management

One of the significant hurdles in material data management is the volume and complexity of inventory and electronic data.

Poor data quality often results from sub-standard, unclear processes and outdated technology.

Without clear processes or standards, manual data management, a lack of ownership and visibility, and organizational changes like mergers and acquisitions, the data becomes unreliable and unusable.

The growth of asset-intensive firms contributes to this challenge, making it imperative to implement efficient processes and technologies. Material inventory management becomes essential for ensuring smooth manufacturing and factory operations.

With only inconsistent and unreliable data available, maintenance and procurement teams find it challenging to efficiently maintain operations, manage inventory, and source parts when needed.

Some of the inefficiencies and consequences of low data quality that cost companies include:

Organizations struggled with materials data scattered across multiple systems, departments, and locations.

The same material might be identified differently in procurement, inventory, maintenance, and accounting systems, causing confusion, redundancies, and operational failures.

Without a unified approach, companies found themselves unable to determine the “single source of truth” for critical materials information.

Without standardized materials data, purchasing departments frequently reordered items already in stock but listed under different codes or descriptions. This led to:

Duplicate inventories occupying valuable warehouse space

Unnecessary capital tied up in redundant stock

Increased carrying costs for excess inventory

Expired or obsolete materials requiring disposal

When maintenance teams couldn’t quickly locate the right spare parts due to poor data quality:

Critical equipment remained offline for extended periods

Production schedules suffered disruptions

Emergency purchasing at premium prices became commonplace

Overall equipment effectiveness (OEE) declined substantially

Poor materials master data created blind spots in the supply chain:

Difficulty tracking material origins and specifications

Inability to monitor supplier performance consistently

Challenges in predicting and preventing material shortages

Limited ability to optimize inventory across multiple locations

Organizations faced significant regulatory and operational risks:

Inability to accurately report on hazardous materials

Difficulty complying with industry regulations and standards

Challenges in material traceability during recalls or audits

Quality issues from using incorrect or substandard materials

As organizations adopted more sophisticated systems, poor materials master data became a critical bottleneck:

ERP implementations failed to deliver promised benefits

Advanced analytics initiatives produced unreliable insights

Digital transformation efforts stalled due to data quality issues

Integration between systems became unnecessarily complex

MRO Materials in SAP are the core components that support maintenance functions, helping avoid unplanned downtime by ensuring the right parts are available when needed.

Materials master data refers to the comprehensive set of information about materials used in a business’ operations, particularly in manufacturing and supply chain management, this is typically why it is also used in relation to MRO solutions, MRO Data Cleansing & Enrichment.

Data Management During ERP Implementation

The integration of Material Master Data Management (MDM) into ERP implementation is not just a value-add, it’s a necessity.

In enterprise-level initiatives like ERP rollouts or consolidations, clean and reliable data forms the foundation for success. Yet, MDM is often overlooked in ERP blueprints, leading to missed opportunities, extended timelines, and higher costs.

One of the biggest gains from aligning MDM with ERP is cost control. Cleansing, standardizing, and enriching data before it enters the ERP system eliminates redundancy, prevents costly errors, and streamlines procurement and inventory, directly improving margins in competitive markets.

Equally important is process integration. MDM breaks down silos, unifies data standards, and enables seamless communication across departments and geographies, boosting collaboration, efficiency, and agility.

During ERP implementations, migrating data from multiple systems, locations, and languages without proper cleansing can cause inconsistencies, delays, and even failures.

MDM mitigates these risks through strong governance, automated classification, normalization, and validation, which are capabilities that ERP systems alone cannot fully deliver.

By embedding MDM into the ERP lifecycle, organizations ensure only accurate, consistent, and reliable data enters the system, setting the stage for long-term operational excellence.

Research by Aberdeen shows that integrating MDM into ERP projects can deliver measurable improvements in performance and ROI.

Optimized ROI from ERP implementation with MDM Integrated

Based on earlier detailed statistics, it can be easily concluded that implementing an MDM initiative during an ERP implementation using automated solutions that combine AI-based technology and deep domain expertise can ensure the success of the project.

Master Data Management can unlock the true potential of an ERP implementation project and achieve expected results.

Who Owns The Material Master Within An Asset-intensive Organization?

Managing material master data is complex, especially when it’s owned by multiple divisions such as IT (Supply Chain), Plant Supervisors, Procurement, and Operations.

This fragmented ownership often leads to confusion and inefficiency.

To stay competitive, organizations must invest in material master data cleansing, partnering with enterprise software providers that specialize in the material domain is a step in the right direction.

Clean, granular data improves operational efficiency, enhances inventory optimization, and delivers strong ROI.

The key to success lies in choosing the right technology to automate item master management. This includes ensuring consistent data quality, deploying evolving solutions for maximum ROI, and selecting systems that can scale with operations.

With the growing importance of master data, businesses should work with domain-specific experts to unlock significant returns and long-term efficiency.

The Business Case For Material Master Data Management

Research from leading analyst firms have found that reduced material costs and optimized inventory, enabled by harmonized and subsequently maintained material master data, can contribute more than 1/3rd of the hard dollar savings from an ERP consolidation initiative.

Success Metrics for Business Led Material Master Data Quality with MDG

Let’s get to some real numbers based on more than 50 implementations.

Reducing Maverick Spend:

In many industries, 30–50% of spend is unmanaged, costing about 17% more than managed spend.

A realistic target is reducing maverick spend by 50% each year for three years through improved material master data quality and MDG search capabilities that align legacy naming with current taxonomies.

Reducing MRO Inventory:

Identifying exact duplicates can cut inventory by 4–8%, while spotting “form, fit, and function” equivalents adds another 6–12% reduction. Real-time detection prevents future inventory bloat.

Leveraging Economies of Scale:

Attribute-level visibility enables better sourcing, volume consolidation, and preferred supplier usage, delivering 5–15% savings. MDG tools handle the heavy data work so commodity managers can focus on strategy.

Reducing New Requests & Approval Time:

Clean, searchable data and duplicate prevention reduce unnecessary new item requests by up to 75% in a year. Automated workflows can shrink approval cycles from 7 days to just 4 hours, saving costs from expedited shipping, local purchases, and downtime.

Use Case: A Global Oil & Gas Giant

The oil and gas industry is capital-intensive, with complex operations where even small disruptions can cause multimillion-dollar losses. A major but often overlooked risk lies in poor material master data (MMD) quality.

For Company A, a $10B petroleum leader, a near-miss occurred when a part request for a “Radial” bearing was mistakenly matched in the ERP to a “Standard” bearing, only a single overlooked attribute separating the two.

Such errors can delay maintenance, cause equipment failure, and halt production.

Partnering with an MDM specialist, the company introduced attribute-based governance, making fields like “bearing type” mandatory. This ensured consistent, normalized records from the point of entry.

Results:

Major reduction in stock discrepancies through precise, attribute-based identification

More accurate forecasting and maintenance planning

Optimized safety stock and reduced obsolescence risk

Better lifecycle and alternate-part visibility

Use Case: Food & Beverage Conglomerate

In the food and beverage industry, safety and precision are non-negotiable—yet even small material master data (MMD) errors can trigger recalls, shutdowns, and regulatory trouble.

The Challenge

Company B, a $5B F&B conglomerate, runs a high-capacity Midwest plant producing beverages, sauces, and frozen meals. During pump replacement on a bottling line, the ERP listed:

Pump, Centrifugal; 30 GPM; Stainless Steel

The correct part, however, required the “Food-Grade” attribute. Missing this detail risked contamination, non-compliance, and millions in losses.

The Solution

Partnering with an MMDM specialist, the company implemented attribute-driven governance—mandatory fields for pump type, flow capacity, material, and certification status. For food lines, only certified food-grade pumps now appear in search results.

Business Impact

Ordering errors eliminated through standardized attributes

Higher uptime and first-time-right procurement

Faster approvals and fewer urgent orders

Stronger compliance and audit readiness

Executing a Materials Master Data Management Strategy

The roadmap for a fool-proof materials master data (MMD) plan mirrors strategies used for different master data domains, like supplier, customer, and product data, but with added focus on industry expertise, turnaround time, and output quality.

In theory, it’s simple: clean unreliable data, validate it against predefined rules for uniqueness, categorization, and completeness, then map it in the ERP with robust governance to prevent future contamination.

This can be done in-house with MRO, database, and IT experts, but many organizations lack such talent or prefer partnering with specialists like Verdantis, who bring deep MMD expertise and governance know-how.

Materials Data Cleansing

Over time, the absence of data governance and stewardship compromises an organization’s materials master data. This leads to duplicate entries, often caused by poor categorization and missing details like manufacturer part numbers or supplier names.

Traditionally, fixing this meant manual data cleansing with pattern matching, fuzzy matching, and “spreadsheet magic.”

While this improves efficiency by removing duplication, reducing errors, and enabling smoother collaboration across departments, it is slow and labor-intensive.

At Verdantis, we now use industry-trained AI and machine learning models to cleanse, standardize, harmonize, and enrich materials master data with greater speed, accuracy, and reliability.

Our Harmonize© suite processes material records in minutes, applies the input rules, and completes processing within hours. All results are manually verified before ERP updates, ensuring complete accuracy.

The video below explains how Harmonize can restore reliability to your legacy master data.

Annual Inventory Carry cost reductions of 4.4% (Factored cost of capital) as write-down (Positive impact to balance sheet)

- 400 Million in Inventory

- 10% Duplicate Identification

- 40 Million in Duplicate Inventory value

- Write Down of Factored Costs at 4.4% of 40 Million = $1,760,000

Cost Reduction on aggregation of demand across 15% of $1BN in MRO

- 1 Billion in Maintenance, Repair and Operations Material

- 15% Identified through Harmonization as Similar (Across 10% Supplier Base)

- 150 Million addressable spend

- 12.5% reduction in costs through strategic sourcing

- Cost Reduction of 12.5% of $150 Million = $18,000,000

ANNUALIZED NET COST REDUCTIONS FROM : DATA CLEANSING = $19,760,000

Materials Data Governance

While Harmonize keeps historical materials data clean and current, preventing future errors requires a strong data governance strategy. This ensures every material request is complete and free of duplicates.

Data governance is typically overseen by a Data Steward or Head of Master Data. Many enterprises use built-in ERP governance tools such as SAP MDG or Oracle MDM, but these legacy systems often need dedicated teams to manage and customize for industry-specific needs.

Verdantis’ Integrity© is purpose-built for materials master management, addressing governance requirements in asset-intensive sectors.

It works as a standalone platform or integrates with tools like SAP MDM, enabling faster enrichment, cleansing, and classification of materials data at scale.

These are the industries that Verdantis focuses on, each with its own unique MRO and direct material data challenges:

Verdantis Integrity for Reduction of Maverick Spend

- 80% of the 1B Maintenance, Repair and Operation Spending is covered by preferred / pre-negotiated contracts – $800 Million in Spend

- Data Governance improved Catalogue Quality –Reduced Maverick Spend from 40% to 25%

- 15% gain in compliance = an additional 120 Million in contracted spending

- Average of 16.5% Cost Reduction for pre-negotiated categories

- Cost Reduction of 16.5% of 120 Million = $19,800,000

ANNUALIZED NET COST REDUCTIONS FROM DATA GOVERNANCE = $19,800,000

COMBINED ANNUALIZED NET COST REDUCTIONS: $39,560,000

High-quality materials master data is not just a data management concern, instead, it’s a critical enabler of operational efficiency, cost control, and maintenance reliability in asset-intensive environments.

Without a strong foundation of clean, enriched, and standardized materials data, organizations face duplicate inventory, delayed procurement cycles, and preventable downtime.

Verdantis helps enterprises take control of their materials master through AI-driven classification, deduplication, and enrichment, delivering a single source of truth across ERP landscapes.

By establishing accurate and centralized inventory data, enterprises unlock greater visibility, automation, and value from their MRO and direct materials operations.

Whether you’re looking to support a data harmonization initiative or prepare for an ERP transformation, our purpose-built platform ensures your materials data is ready, clean, complete, and trusted.

How do poor materials master records affect procurement and inventory planning?

Duplicate or inaccurate materials data results in redundant purchases, maverick spend, and inflated inventory carrying costs. Procurement teams often fail to leverage volume-based discounts due to fragmented item records. Planners may either understock critical parts or overstock non-movers, both of which erode working capital and increase operational risk.

What are the key business outcomes organizations see after implementing Verdantis’ materials data cleansing and enrichment?

Customers typically see:

10–15% reduction in inventory carrying costs due to duplicate elimination and better visibility.

Improved first-time fix rates and reduced MTTR through structured asset–part relationships.

20–30% indirect spend savings by streamlining procurement and avoiding emergency buys.

Enhanced readiness for ERP/EAM upgrades, mergers, or regional standardization efforts.

Verdantis’ solutions directly impact working capital, plant uptime, and digital transformation readiness.

What makes Verdantis’ AI engine uniquely suited for materials master data enrichment?

Our AI engine is purpose-built for industrial, engineering, and MRO data contexts, unlike generic NLP tools. It:

Understands free-text item descriptions from legacy systems.

Learns attribute-value pairs from sparse or inconsistent records.

Suggests replacements for obsolete items.

Links materials to equipment BOMs or functional locations.

This vertical specialization makes it highly accurate and relevant for materials data enrichment at enterprise scale.

What KPIs can be used to track the quality and impact of materials master data?

Key metrics include:

% of duplicate-free records

% of records with complete attributes

% classified under standard taxonomy

Material search accuracy and speed

Reduction in material-related downtime or emergency orders

Reduction in indirect spend or inventory carrying costs

Time-to-onboard new materials or vendors